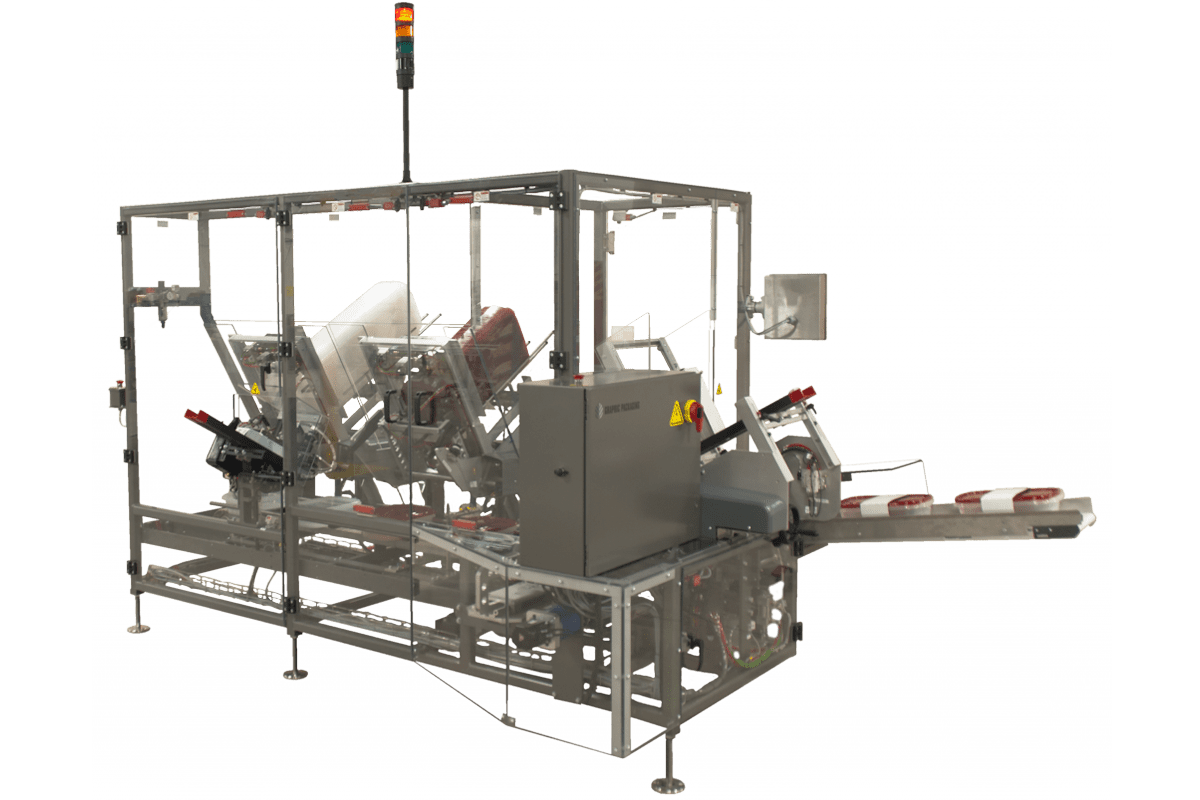

FlexSleeve™

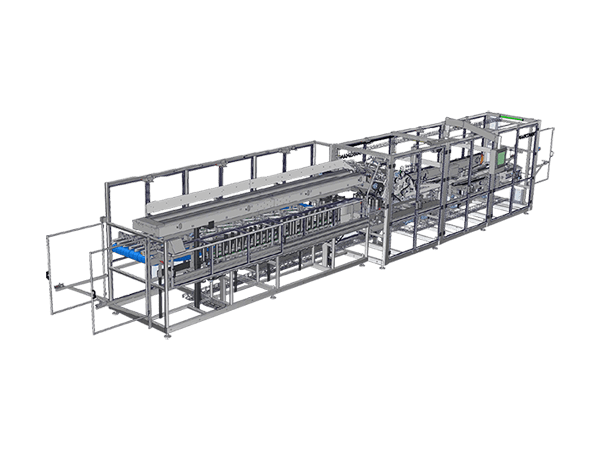

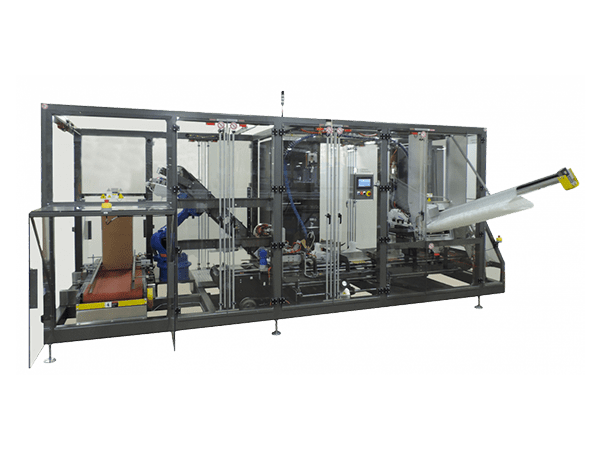

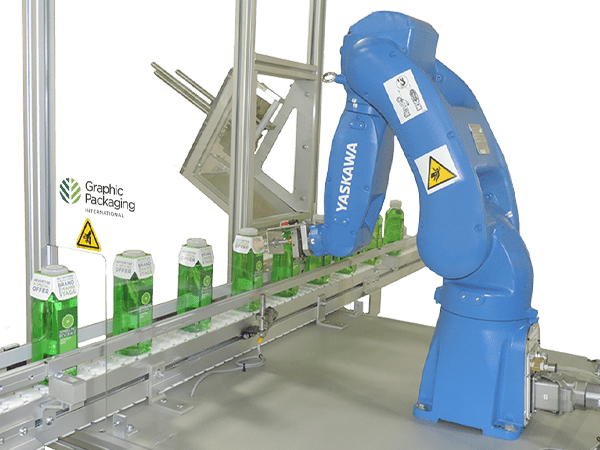

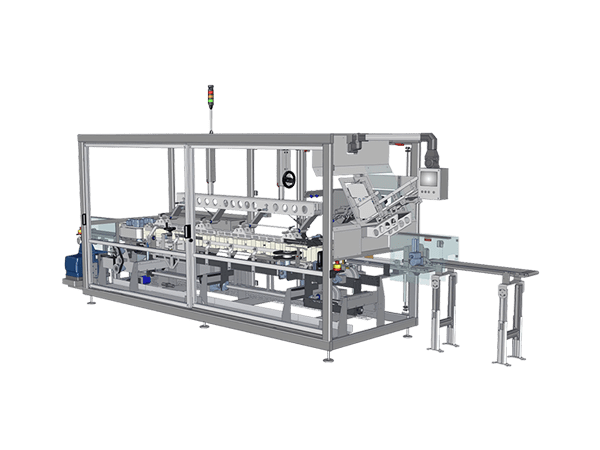

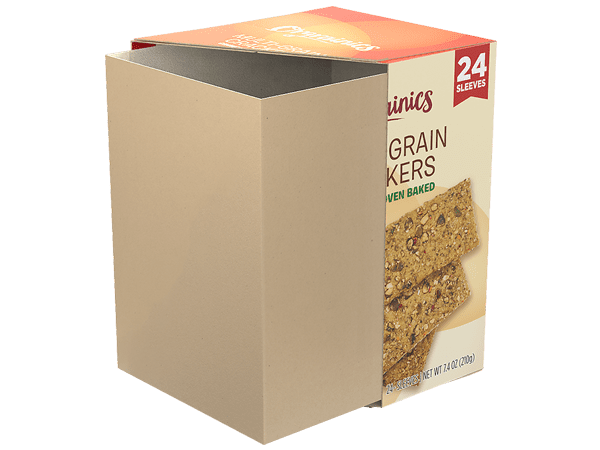

FlexSleeve™ is an intermittent or continuous motion packaging machine that is designed to apply paperboard wraps or sleeves to trays, cups, containers, and other consumer products.

Accommodates a variety of wrap closures, including a mechanical lock, hot melt glue, or pre-glued sleeves.

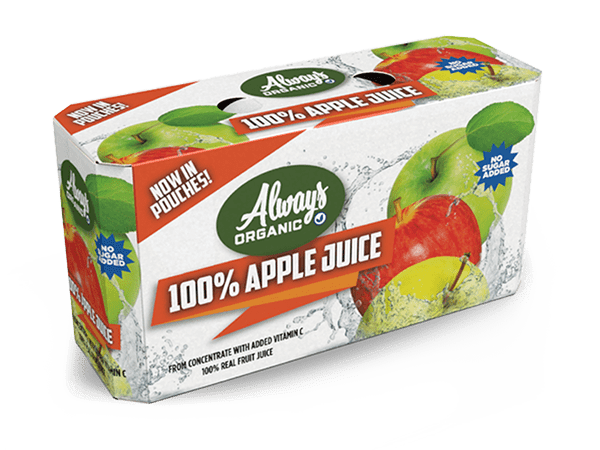

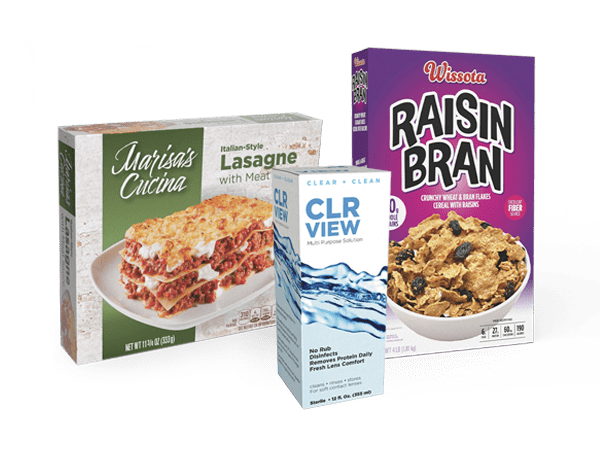

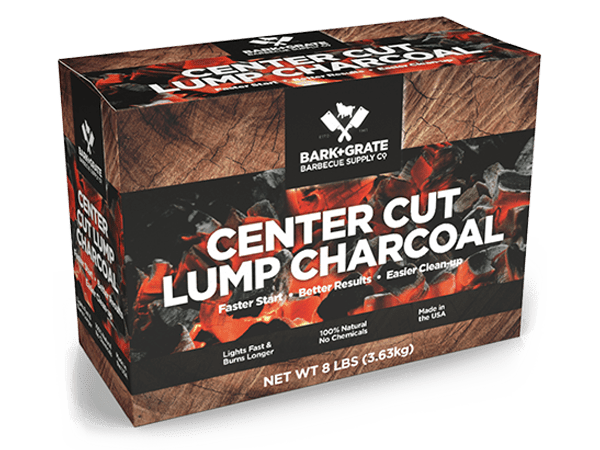

FlexSleeve™ applications include:

- Yogurt cups

- Containers

- Bowls

- Trays

- Consumer products

- Healthcare products

- Collation of empty containers prior to sleeving or wrapping

Quick Links

See the FlexSleeve™ in Action

An intermittent or continuous motion packaging machine that can wrap or sleeve your cups, trays, containers, and more.