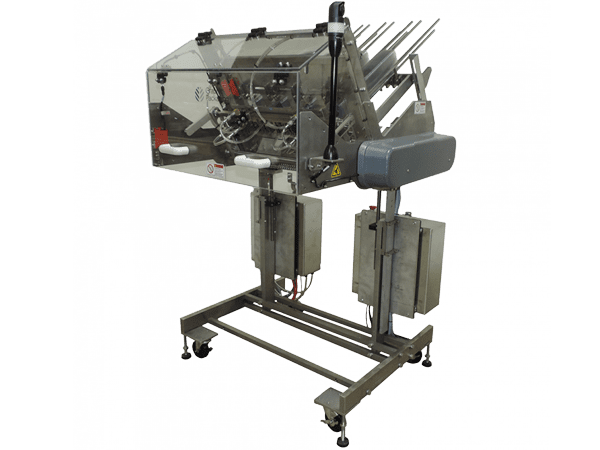

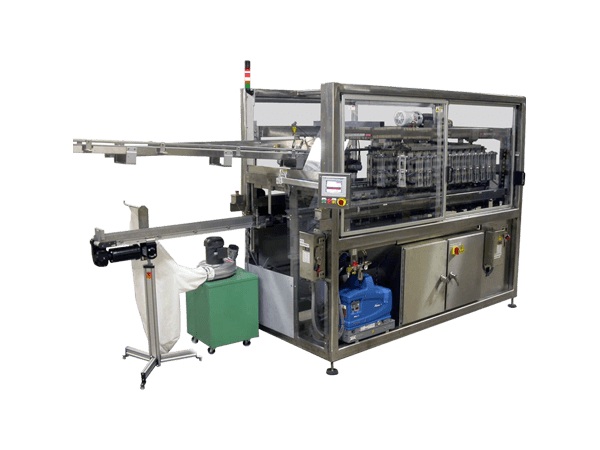

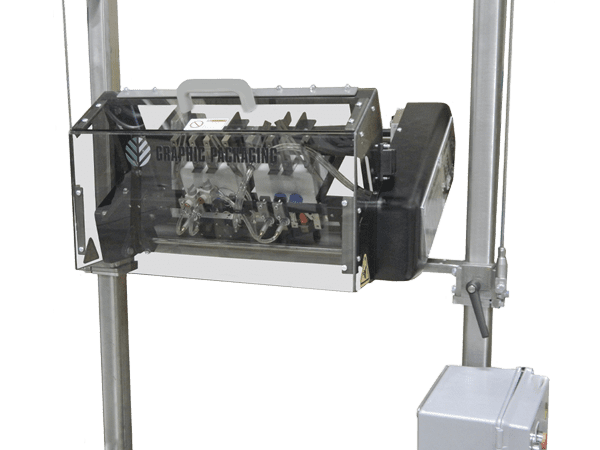

Intermittent Motion Hang Tag Applicator Machine

A flexible, intermittent machine for applying neck and hang tags to bottles. Also known as a reciprocating vacuum placer, the machine can work offline or be integrated into your current production line.

The machine can apply various types of tags, including paper, paperboard, and plastic, as well as a range of different shapes.

Quick Links

See the Hang Tag Applicator Machine in Action

A flexible, intermittent machine for applying neck or hang tags to bottles that can accommodate various tag types and shapes.