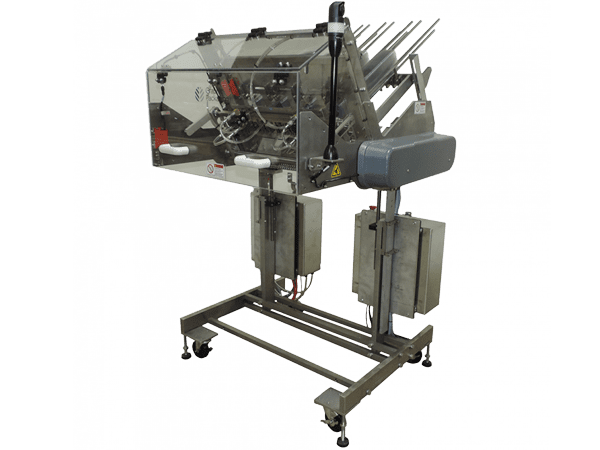

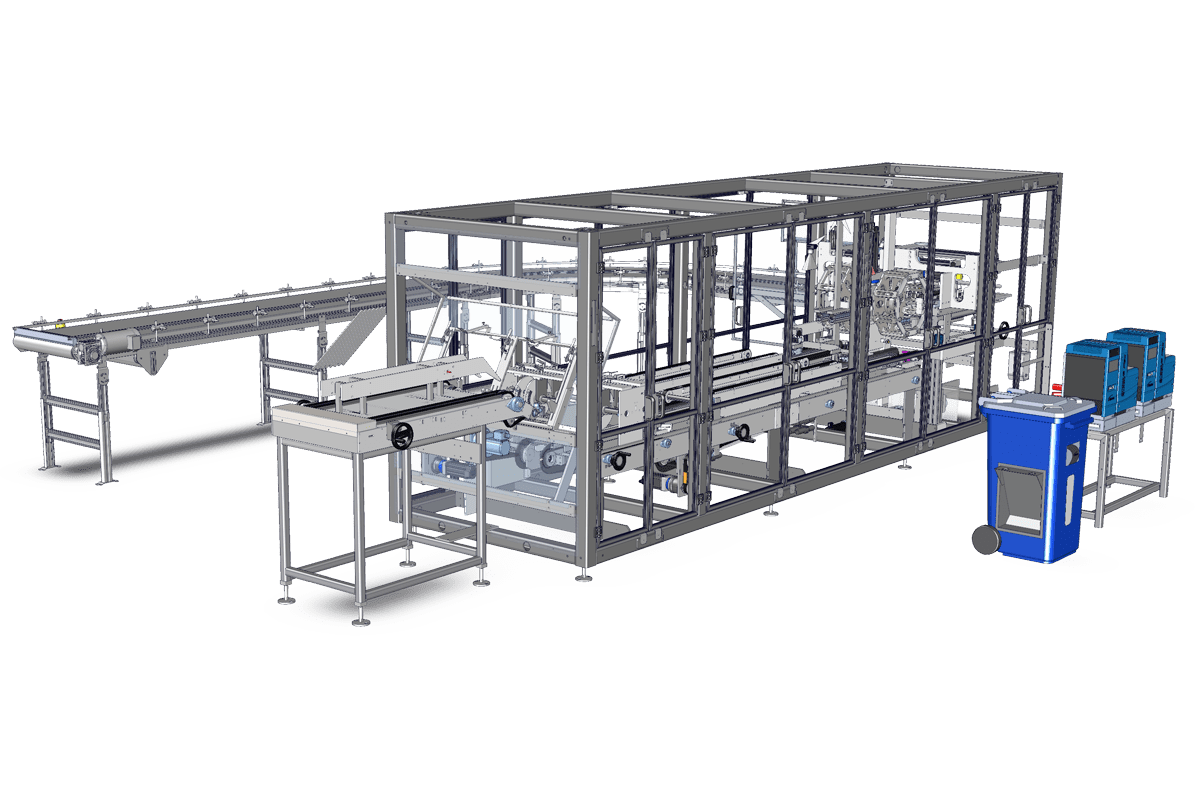

High-Speed Punnet and Tray Former

A flexible, high-speed continuous motion machine designed to form punnet trays and other tray types for hand or automatic top loading of product. Offers a functional and easy-access construction designed to handle a full range of flat blanks for forming punnet trays and other tray types.

Quick Links

See the Punnet and Tray Former in Action

A high-speed, flexible punnet and tray former that offers a tool-free changeover solution.

Punnet and Tray Former Features

Standard Features

- Ergonomic dual 4 ft powered magazine for flat carton blanks

- Reciprocating feeder for reliable carton staging

- Servo-controlled for ease of adjustment

- Tool-free quick-change plunger and cavity mounting

- Hot melt glue system

- Tool-free changeover

- Allen Bradley electrical package

- Color touchscreen HMI and light tower for visual display of machine functions

- Scales and dial indicators for accurate changeovers

- External ethernet port

Optional Features

- Three grades of construction are available from standard finish to a stainless steel wash-down construction

- IQ tablet for technical manuals, parts manuals, 3D PDF part viewer, and dynamic changeover checklist with video guidance

- Tablet includes locking mount that also serves as a dock and recharging station

- Remote connectivity

- Low carton sensing

- Alternative electrical packages