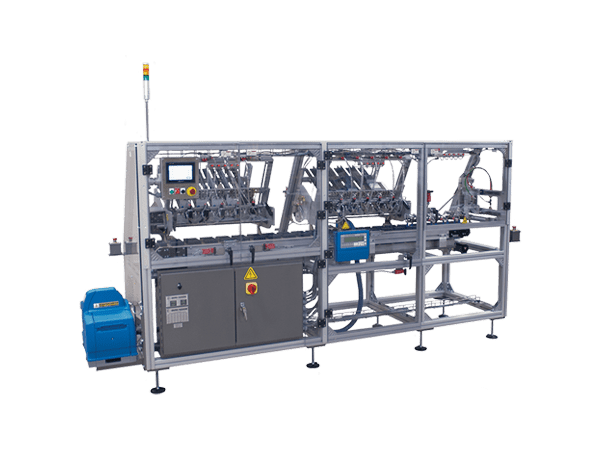

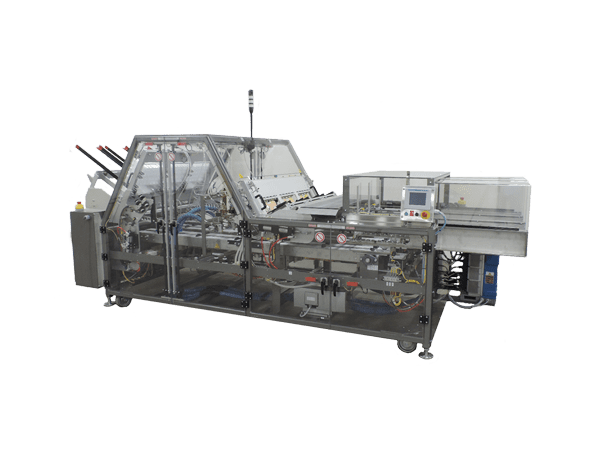

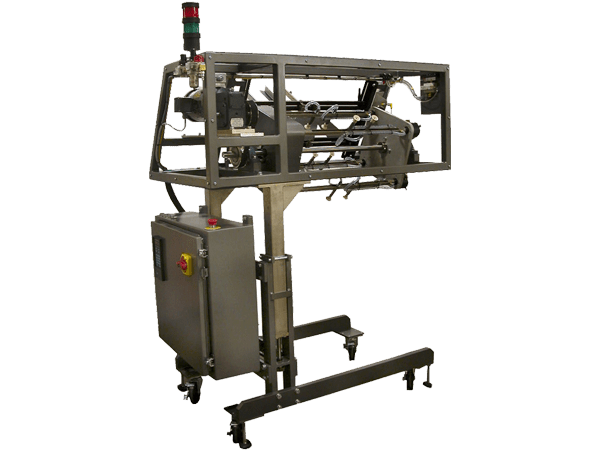

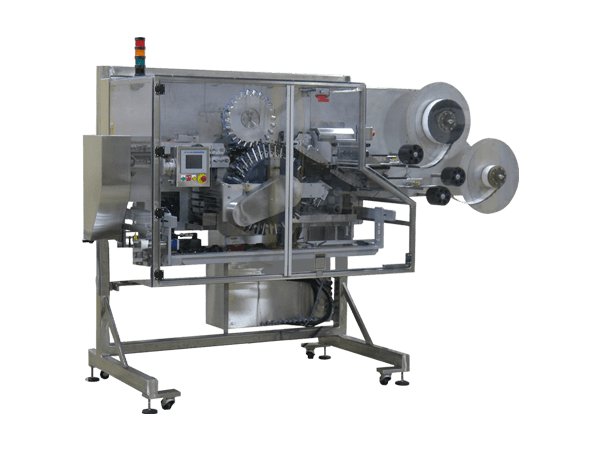

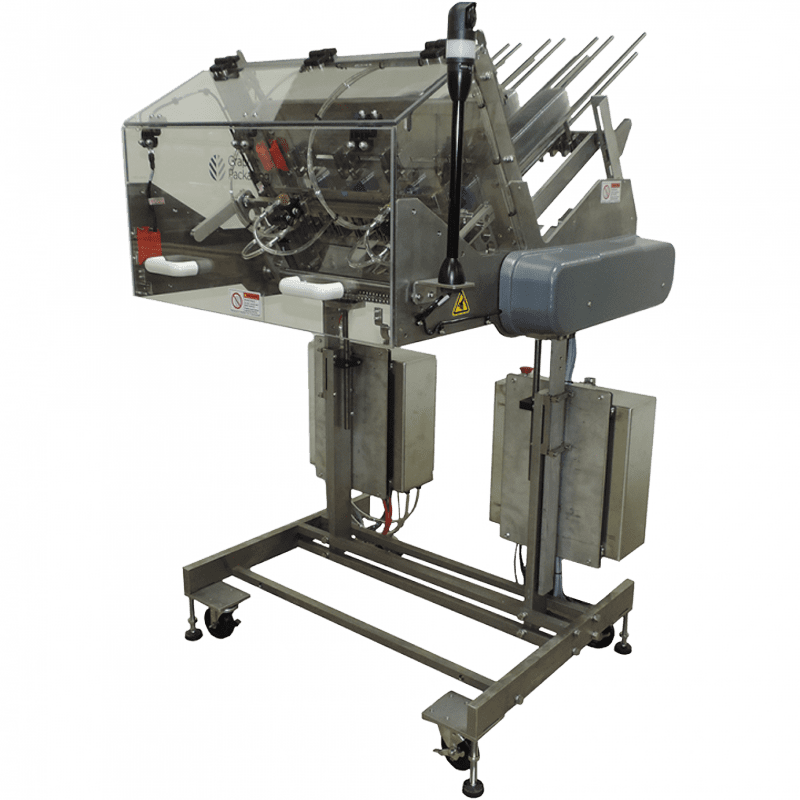

Reciprocating Pick and Place Machines

Reciprocating pick and place machines, also known as placers or denesters, are standalone, flexible, intermittent-motion machines designed for picking and placing a variety of stackable items into or onto another product, or as a tray-feeding device at the front end of a production line.

Available in multiple sizes and three construction grades to match application needs, including water-resistant/wash-down.

Quick Links

See the Reciprocating Pick and Place Machine in Action

A standalone, flexible, intermittent-motion machine designed for picking and placing a variety of stackable items into or onto another product, or as a tray-feeding device at the front end of a production line.