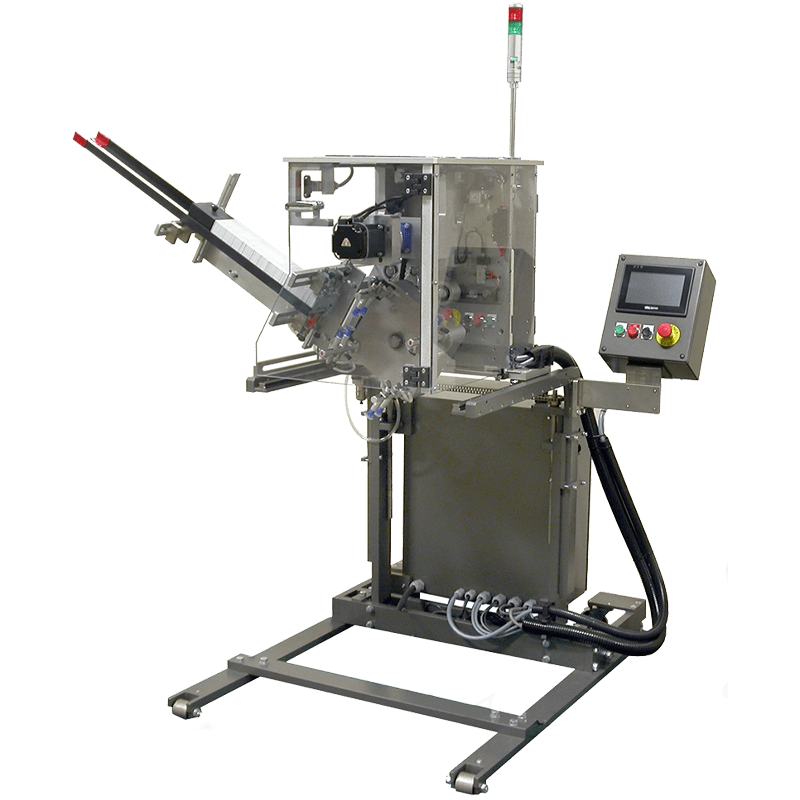

Servo-Driven Rotary Placer

The servo-driven rotary placer is a standalone, continuous motion machine that is designed to pick a variety of stackable items, with precise placement onto another product in a production line. Ideal for handling a variety of products such as CR80 cards, magnets, nested products, and more.

Ideal for integration with print industry equipment or applying backer cards to trays for point-of-purchase stand-up trays at retail.

Quick Links

See the Servo-Driven Rotary Placer in Action

A standalone, continuous motion machine that is designed to pick a variety of stackable items, with precise placement onto another product in a production line.

“We met the accuracy expectations of our customer and eliminated rejects/scrap which resulted in savings of $13,000 from friction feeder performance.”

Major Print Industry Company

Related Machinery

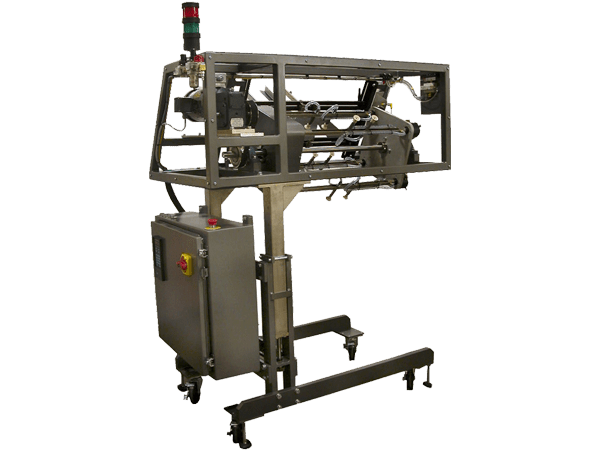

Rotary Vacuum Placers

Rotary vacuum placers are flexible, continuous-motion machines designed for picking a variety of stackable items at high speed with placement onto or into another product on a conveyor or flight system.

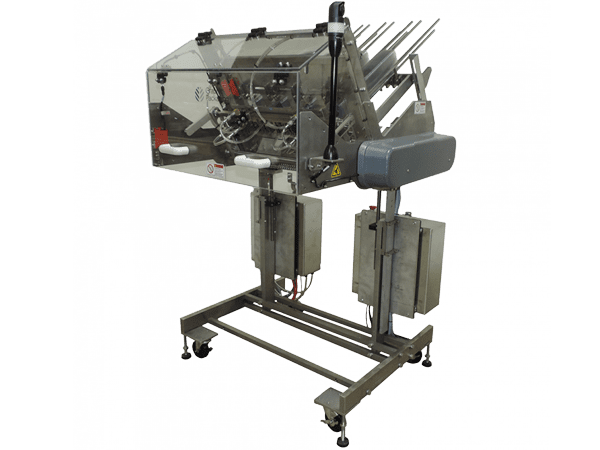

Reciprocating Pick and Place Machines

A standalone, flexible, intermittent-motion machine designed for picking and placing a variety of stackable items at the front of a production line.