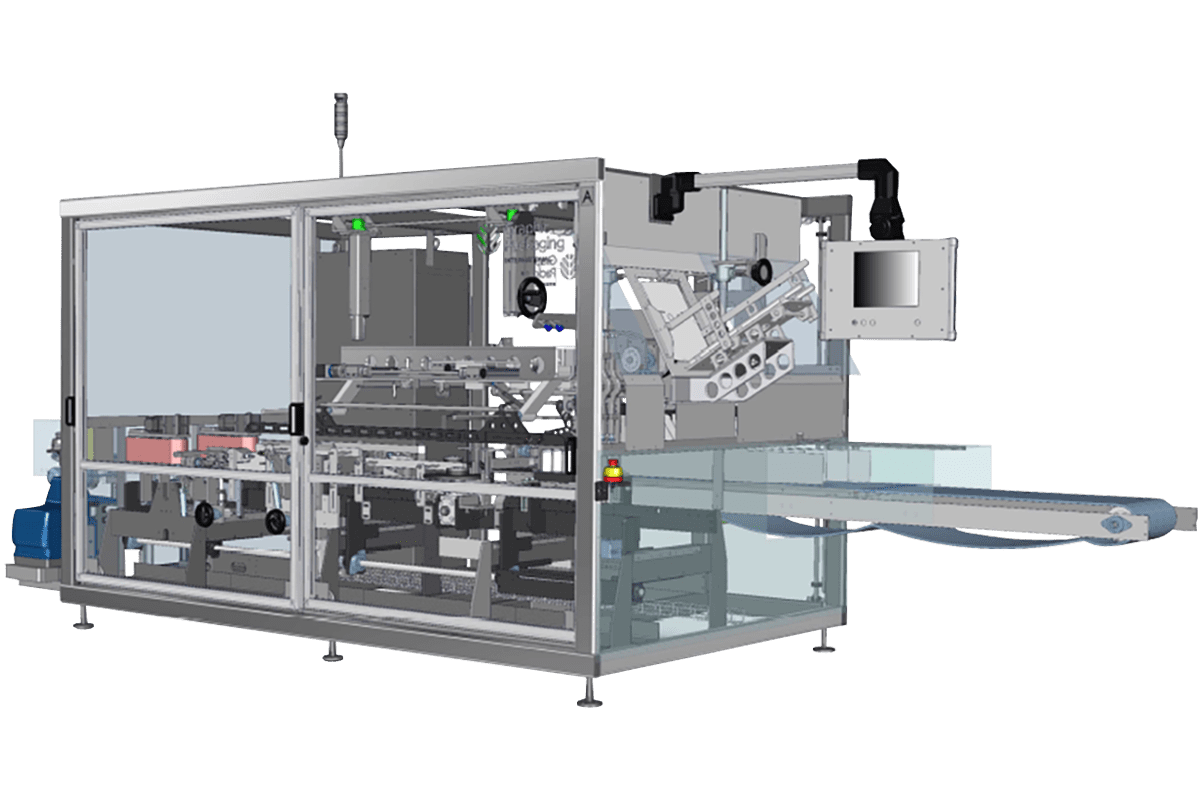

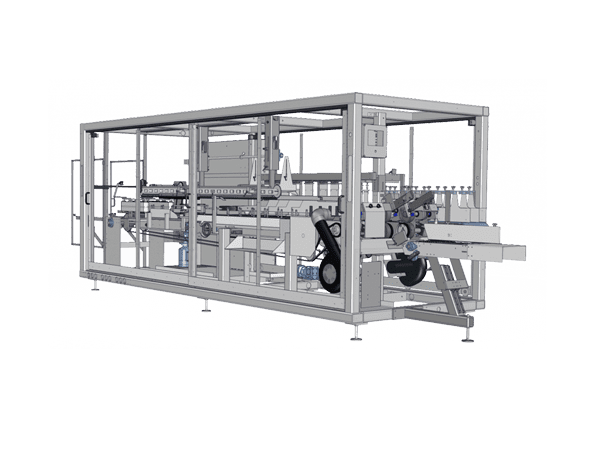

QuikFlex™ 40

The QuikFlex™ 40 is a low-speed, intermittent motion multipack machinery system with a small footprint for fully enclosed packages. It is an ideal solution for automating manual operations for the craft market or for lower speed requirements.

The QuikFlex 40 machine allows great flexibility as it runs from 4-packs to 24-packs, as well as multiple diameters and heights of cans and bottles.

The tool-free changeover technology is quick, simple and repeatable, eliminating time-consuming fine-tuning.