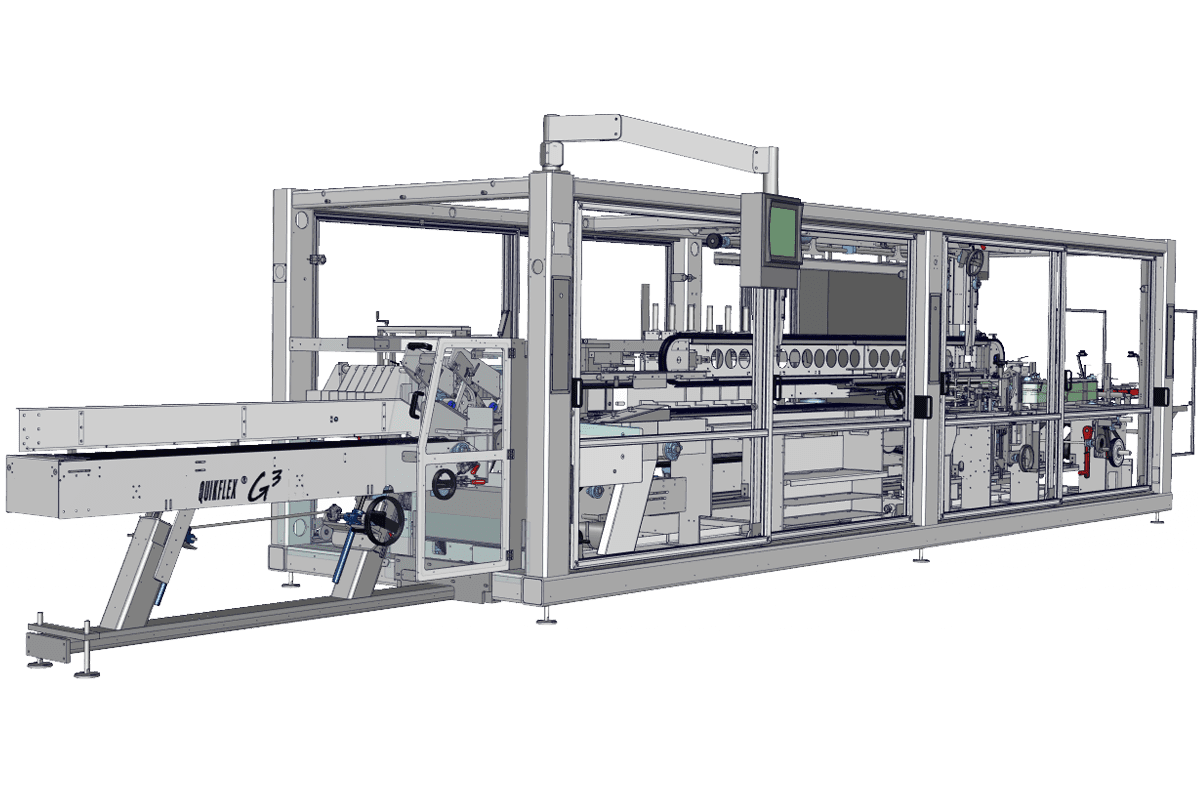

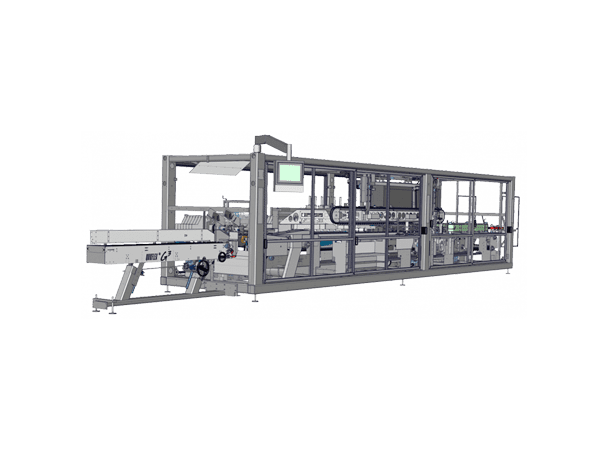

QuikFlex™ 600G3

The QuikFlex™ 600G3 fully enclosed multipack machine is an industry-proven packaging system for multi-diameter/multi-height cans and glass and PET bottles.

This machine features our latest technology for moderate to high-speed requirements on new or existing production lines and can generate 220 packs per minute.

QuikFlex 600G3 Benefits

Operational Efficiency

- Heavy-duty, tubular steel frame

- Clear visibility and sliding guard doors for easy walk-in access

- Fewer parts, adjustments, chains, and drive points; improved accessibility and better carton control from the feeder to the discharge

- Our market-proven predictive maintenance program (PMP) helps plan downtime and enables better budgeting

Convenience

- Quick, simple, and repeatable changeovers

- IQ tablet provides a changeover checklist and video help for a changeover time of 20-70 minutes

QuikFlex 600G3 Specifications

Primary Containers and Pack Configurations

- Cans, glass and PET bottles

- 6, 8, 9, 10, 12, 15, 16, 18, 20 & 24*

*Range dependent on primary container diameters

Speeds

Cans:

- 6.25″ pitch | 200ppm sustained | 220ppm Surge

- 12.5″ pitch | 150ppm Sustained | 180ppm Surge

Bottles:

- 6.25″ pitch | 200ppm sustained | 220ppm surge

- 12.5″ pitch |125ppm sustained | 150ppm surge

Machine Weight

- Approximately 15,000lbs (6,850kg)

Features and Applications

Features

- Right- or left-hand carton loading and controls

- Auto prime and clean-out features

- Walk-in frame

- Text fault display

- 2.5-meter carton magazine

- Ergonomic waist-high carton loading

- Market proven segment wheel feeder

- High volume air assist carton opening

- Wedge metering for smooth product infeed

- Powered overhead

Applications

- Beer

- Craft beer

- Carbonated soft drinks

- Water and sports nutrition

- Coffee and tea

- Dairy

- Spirits and cocktails

- Wine

- Pet care

Related Machinery

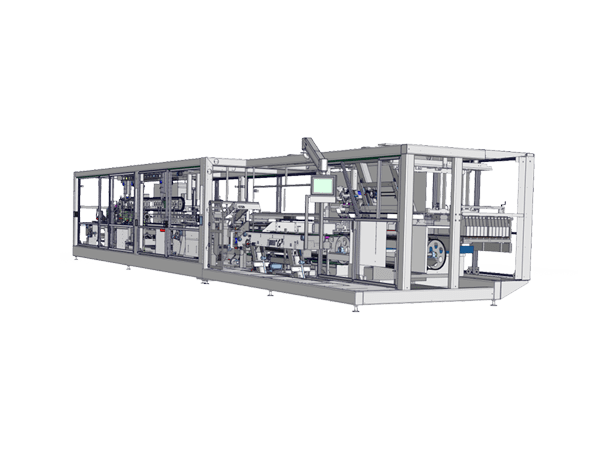

QuikFlex™ TSG3

The QuikFlex™ TSG3 is a fully enclosed, double-tiered multipack packaging machine that can handle multi-diameter/multi-height cans and plastic bottles in a wide range of configurations and package styles.

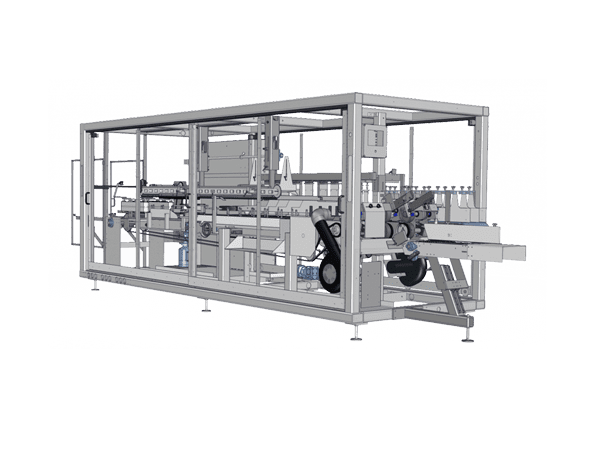

QuikFlex™ 300

The QuikFlex™ 300 is a mid-speed fully enclosed multipack packaging machine that is a cost-effective solution with a small footprint for moderate speed requirements, new product introductions, or market trial applications.

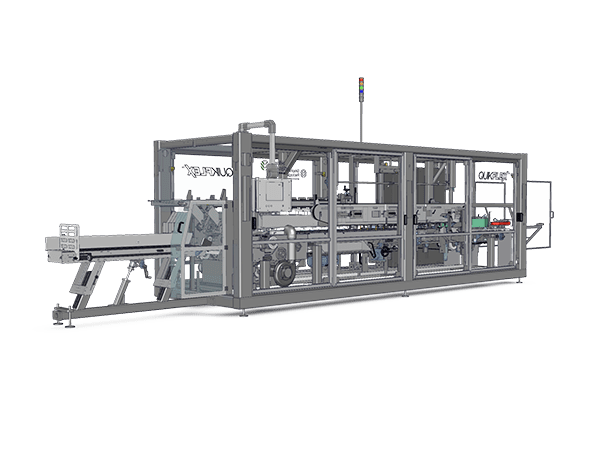

QuikFlex™ 400

The QuikFlex™ 400 machine for fully enclosed packaging is an industry-proven packaging system for a wide range of pack styles and configurations. Works with multi-diameter/multi-height cans and bottles including narrow pack 2×2, 53mm capability.

QuikFlex™ 2100G3

The QuikFlex™ 2100G3 is a fully enclosed multipack machine that can achieve up to 300 packs per minute and can handle a wide range of pack styles and multi-diameter/multi-height cans and aluminum, glass, and PET bottles.

Related Products

Fully Enclosed Multipack Cartons for Food and Beverage

Fully enclosed multipack cartons for beverage, food, and pet food applications deliver maximum coverage to protect and secure your product through the supply chain. The portfolio is ideal for cans and plastic, glass and aluminum bottles.