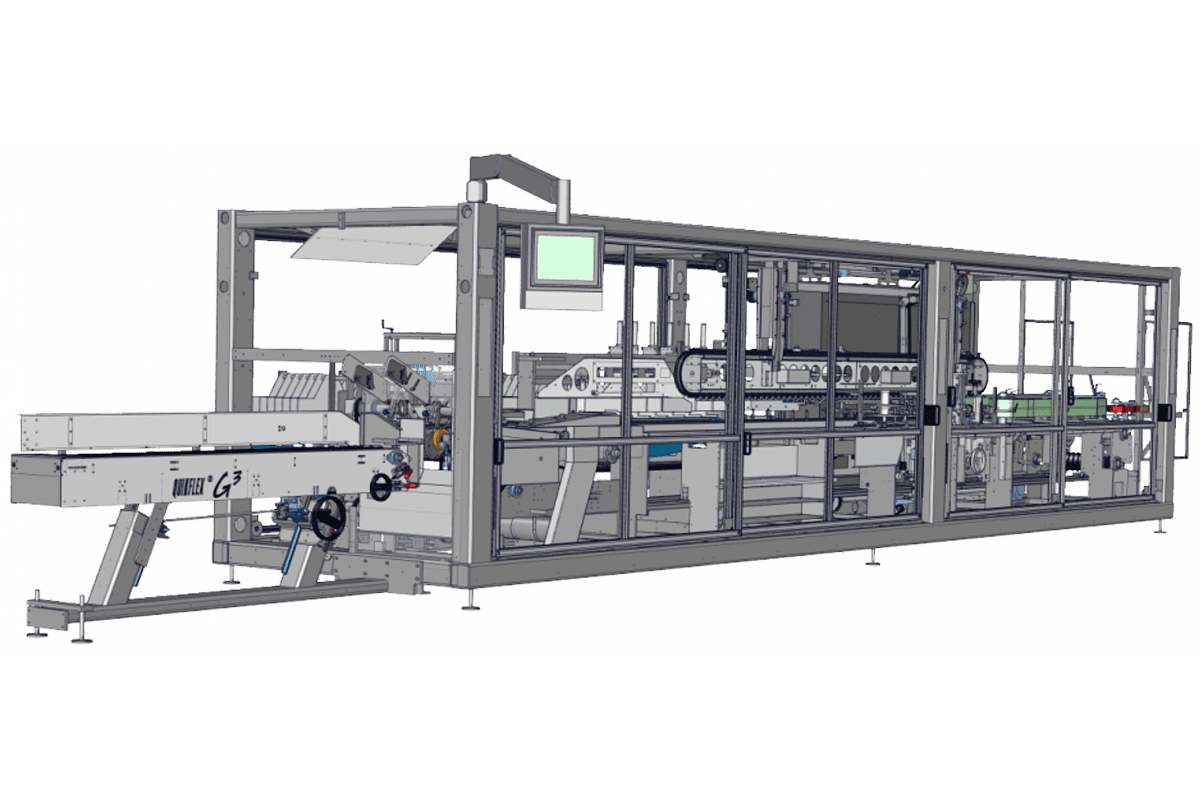

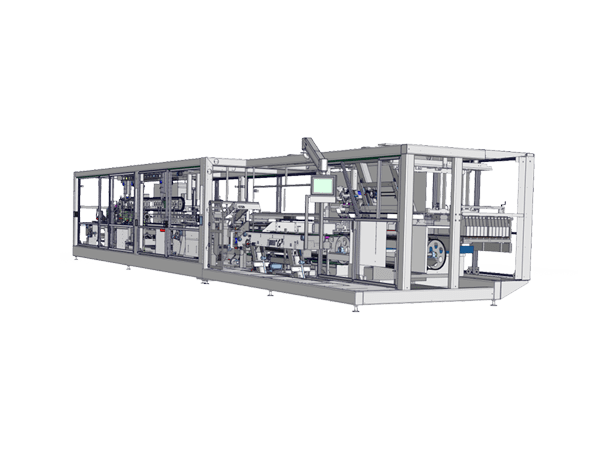

QuikFlex™ 2100G3

The QuikFlex™ 2100G3 is a fully enclosed multipack machine that can handle a wide range of pack styles and configurations, offering the flexibility to work with multi-diameter/multi-height cans, and aluminum, glass, and PET bottles.

This machine accommodates the highest speed requirements on new or existing product lines.

The main features of the QuikFlex 2100G3 include tool-free changeovers, functional design for easy access, and it is powered overhead.

Quick Links

See the QuikFlex 2100G3 in Action

QuikFlex 2100G3 is a high-speed, fully enclosed multipack packaging machine that can handle multi-diameter and multi-height aluminum cans and bottles.

Related Machinery

QuikFlex™ TSG3

The QuikFlex™ TSG3 is a fully enclosed, double-tiered multipack packaging machine that can handle multi-diameter/multi-height cans and plastic bottles in a wide range of configurations and package styles.

Related Machinery

Fully Enclosed Multipack Cartons for Food and Beverage

Fully enclosed multipack cartons for beverage, food, and pet food applications deliver maximum coverage to protect and secure your product through the supply chain. The portfolio is ideal for cans and plastic, glass and aluminum bottles.