Fortress™ Cupstock

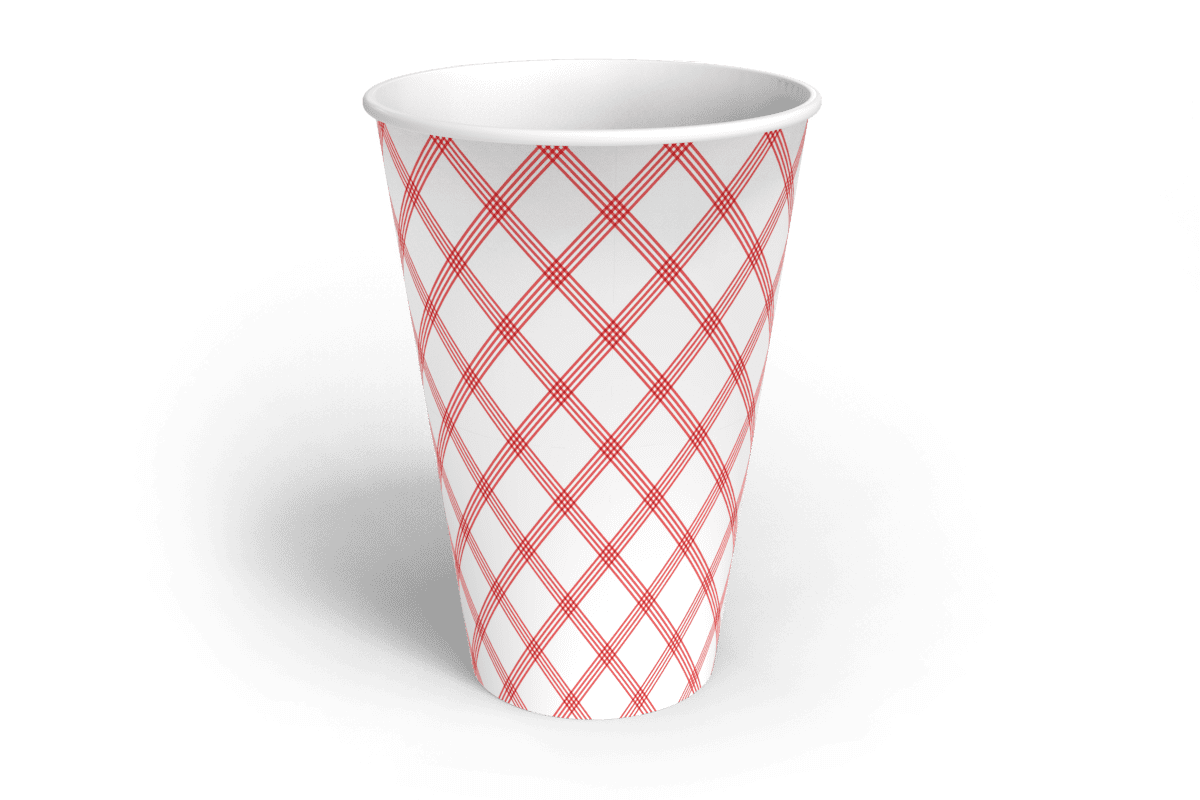

With a durable liquid barrier, excellent sealing properties, exceptional material purity, and an ideal printing surface for high-quality graphics, Fortress™ Cupstock is designed to make a great impression from the first look to the last drop.

Fortress Cupstock provides exceptional liquid holdout and good wicking resistance. It is made from bleached paperboard (also know as solid bleached sulfate or SBS) made from renewable plant-based fiber from sustainably managed forests.

Quick Links

learn more

Fortress Cupstock

Product Information

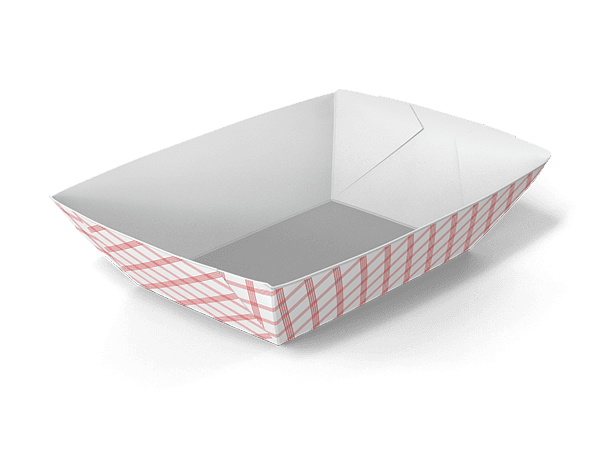

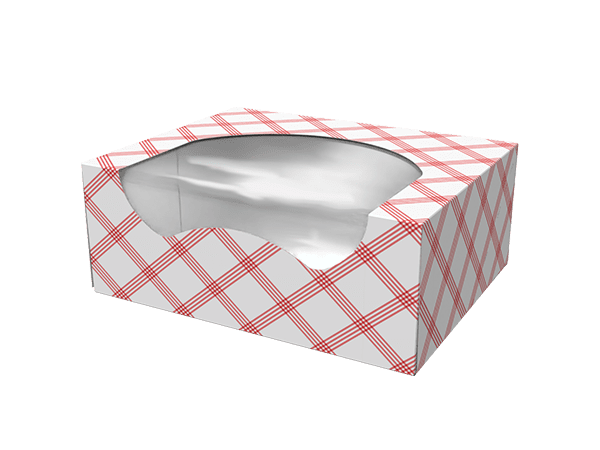

Applications

- To-go beverages

- Quick service restaurants

Benefits

Excellent printability and glue adherence

- Fortress Cupstock provides an excellent sheet surface for consistent press performance. The superior printing surface of Fortress Cupstock will ensure that your cup truly is your brand’s billboard.

- With a clean blue-white shade, your cups will look clean and crisp in any application

Consistent performance in a variety of environments and converting rocesses

- With North America’s largest cupstock machine producing only Fortress Cupstock, you can depend on consistent board from run to run to ensure efficient operation in your converting facility

- Fortress Cupstock provides exceptional liquid holdout and good wicking resistance

- 100% web inspection on all cupstock extruders plus a consistent array of TAPPI testing procedures ensures that your board will be clean and reliable

Range of options

- Whether your application requires LDPE on only one side for a hot cup or on both sides for additional barrier protection, Fortress Cupstock offers a variety of polyethylene options and specifications to suit your project needs

- Available in a wide variety of coat weight combinations, as well as with heat sealing primer for good seam and rim sealing or a treated surface to ensure that your graphics reflect your brand image

Specifications

| Basestock Properties | Units | 11pt | 12.3pt | 13.2pt | 14pt | 15.3pt | 16.3pt | 17pt | 18pt | 19pt | 20pt | 22pt | 24pt | Standard |

| Caliper | Inches | 0.011 | 0.0123 | 0.0132 | 0.014 | 0.0153 | 0.0163 | 0.017 | 0.018 | 0.019 | 0.020 | 0.022 | 0.024 | T-411 |

| Thickness | Microns | 279 | 312 | 335 | 356 | 389 | 414 | 432 | 457 | 483 | 508 | 559 | 610 | T-411 |

| Brightness | GE | 82 | 82 | 82 | 82 | 82 | 82 | 82 | 82 | 82 | 82 | 82 | 82 | T-452 |

Compliance

Food contact compliance

- FDA and EU compliant for contact with dry foods, as well as aqueous and fatty foods

Food contact compliance (USA)

- 21 CFR 176.170 (components of paper and paperboard in contact with aqueous and fatty foods)

- 21 CFR 176.180 (components of paper and paperboard in contact with dry foods)

Food contact compliance (EU)

- Article 3 of Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food

- Commission Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food, as applicable

- Manufactured in accordance with Commission Regulation (EC) No 2023/06 on good manufacturing practice for materials and articles intended to come into contact with food