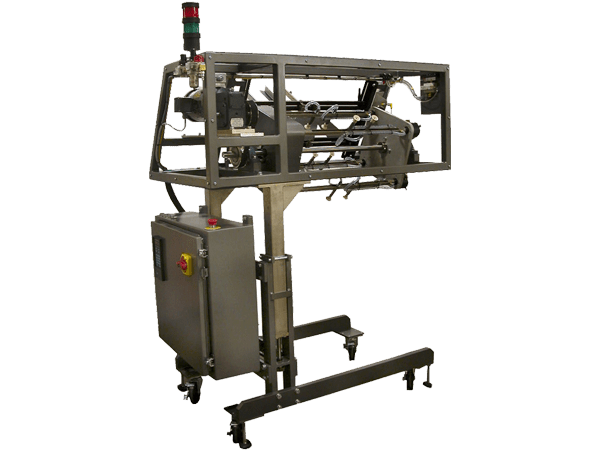

Clamshell Labeling Machine

A high-speed, continuous-motion machine designed for labeling and re-nesting clamshells and trays, with tray counting functionality for distribution.

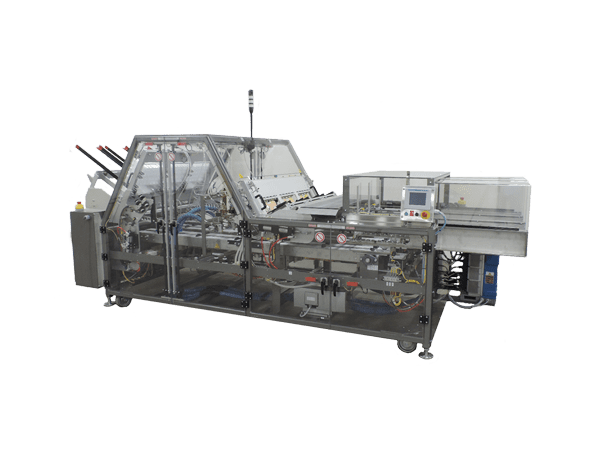

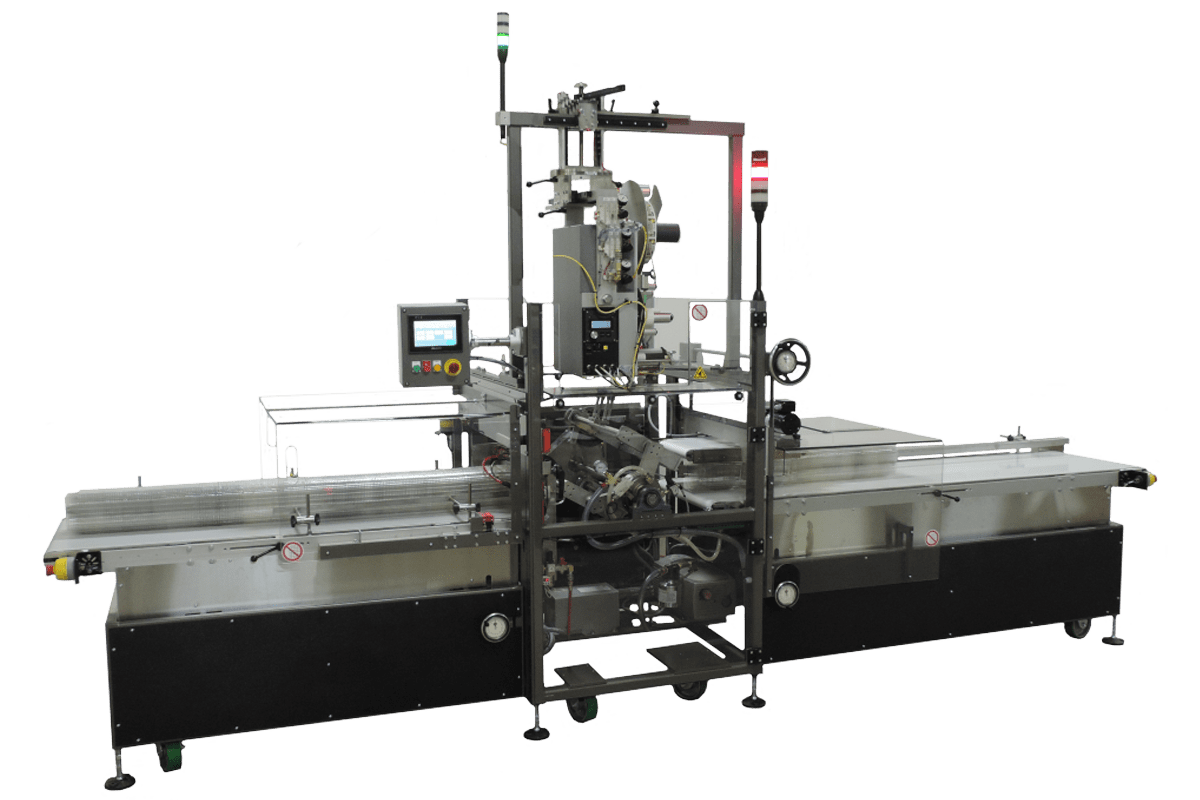

The system utilizes a three-arm, four-stop patented secondary motion rotary placer for picking of product, a 6″ horizontal powered infeed magazine to stage product for labeling, and an 8″ horizontal powered outfeed magazine with overhead guide belts to accumulate labeled product.

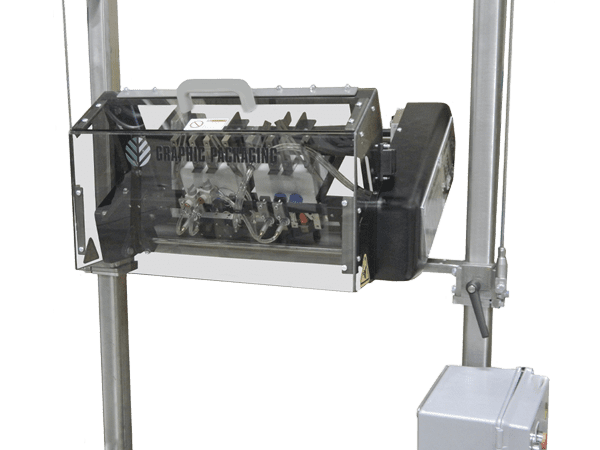

One tamp-style labeler is integrated with this machine to label the top lid, or two tamp-style labelers can be integrated to label both the lid and the base.

Finishes, enhancements, and capabilities include heavy-duty cold rolled welded steel frame made with 1-1/2” square mechanical tubing.

Quick Links

See the Clamshell Labeling Machine in Action

A high-speed, continuous-motion machine designed for labeling and re-nesting clamshells and trays, with tray counting functionality for distribution.