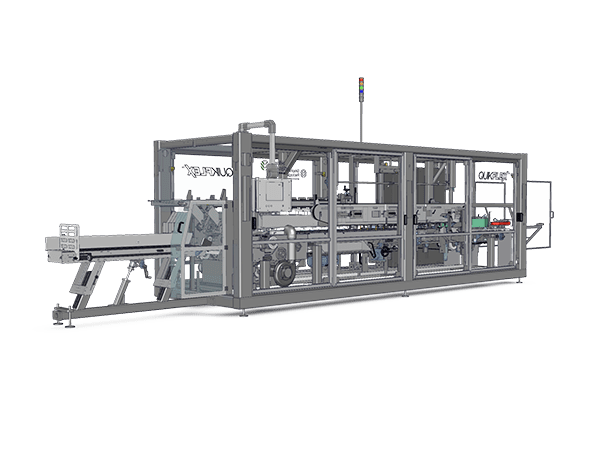

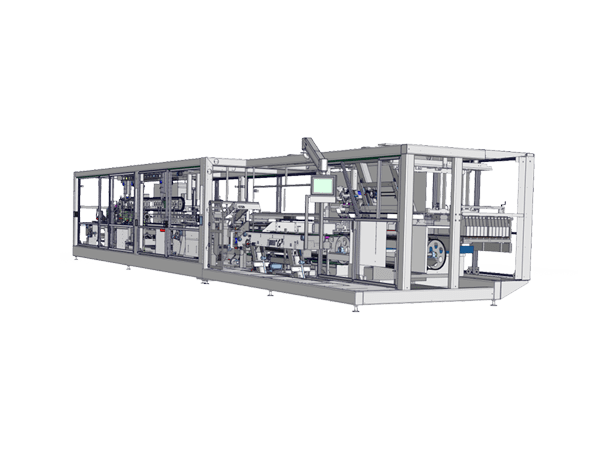

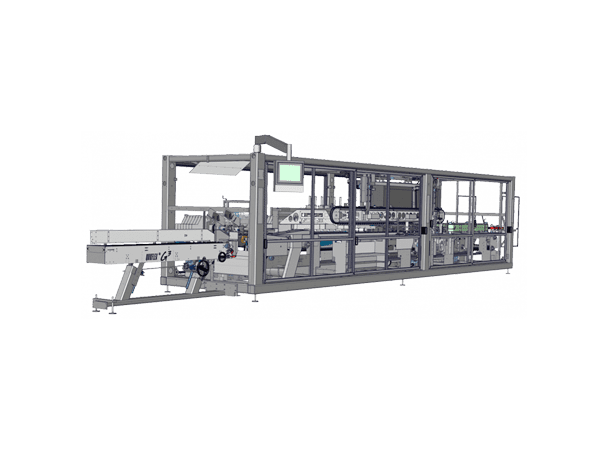

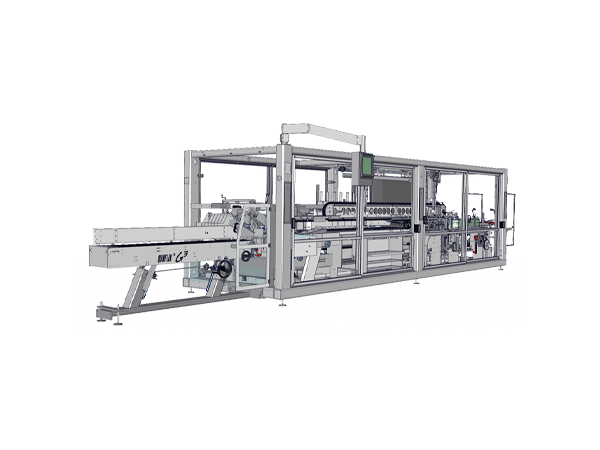

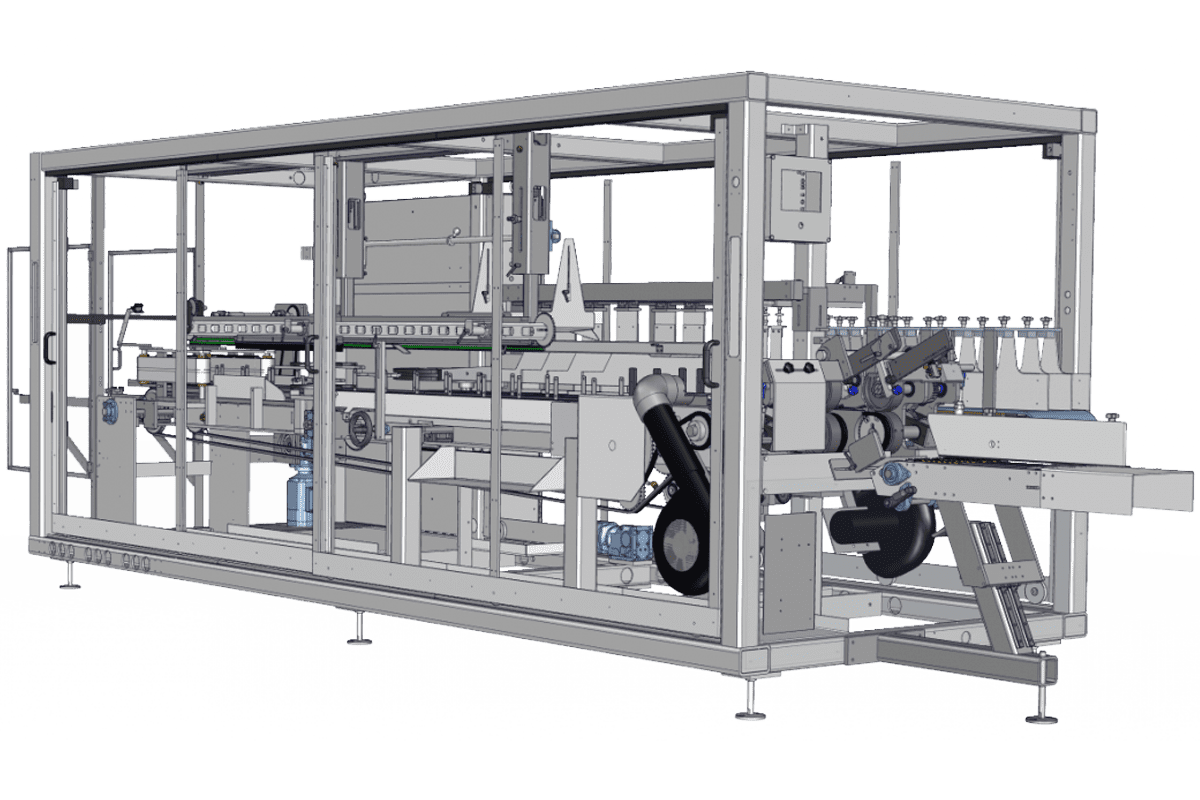

QuikFlex™ 300

The QuikFlex™ 300 is a mid-speed, fully enclosed multipack packaging machine that is a cost-effective solution with a small footprint for moderate speed requirements, new product introductions, or market trial applications. It can run all cylindrical primary container types including cans and bottles.

Its design not only has fewer parts, adjustments, drive points, and chains, it also offers simpler timing and better accessibility and carton control from the feeder to the discharge.

Quick Links

See the QuikFlex 300 in Action

The QuikFlex 300 design not only has fewer parts, adjustments, drive points, and chains, it also offers simpler timing and better accessibility and carton control from the feeder to the discharge.