article

Graphic Packaging at Fruit Attraction: Innovations and Insights

Fruit Attraction is always one of the key events in the produce sector’s calendar, and this year was no exception. It attracted over 90,000 visitors from 130 countries, with more than 1,800 exhibitors from across the global fresh produce, packaging, supply chain, and biotech industries. Graphic Packaging was delighted to be one of those exhibitors.

The impact of tightening plastic packaging laws around the world meant that this year’s event was arguably more important than ever to produce stakeholders from across the industry. Our team had some great conversations with visitors to our stand, many of whom were growers and packers looking for packaging solutions that would help them achieve their packaging goals. Many of these conversations were with UK business stakeholders who had questions about the state of the British produce sector.

The recent introduction of the UK’s plastic packaging tax, plus new legislation in France and upcoming legislation in Spain banning plastic packaging for certain produce, meant that the focus was firmly on alternative solutions for fresh produce. Plastic alternatives and plastic reduction solutions were the hot topics on the stand.

Unsurprisingly, some questions came up more than others. So below, you’ll find the burning questions that we were asked during our time in Madrid.

Can I really achieve plastic-free packaging?

Many of the discussions at Fruit Attraction revolved around this priority for the produce sector as shifting consumer preferences and increased legislation put pressure on plastic packaging.

Applications that are not sensitive or which do not require MAP can be made from 100 percent cartonboard, with a moisture or grease-resistant coating if required. Everything from cherry tomatoes to apples, oranges to avocados can be safely packaged in plastic-free packaging (considering the definition of plastic in the single use plastic directive that excludes external varnish and adhesives from the definition).

In addition, several EU-funded projects, such as Preserve and BioSuPack, are exploring the potential of bio-based barrier coatings as alternatives to fossil-derived plastic.

Can I achieve an equivalent shelf-life to plastic with fibre-based packaging?

Fibre-based packaging offers excellent protection through the supply chain and has been found to reduce product damage in certain applications. A notable example of this can be found in our work with apple distributor Belle Harvest.

The US-based distributor wanted to replace their plastic bag with a more sustainable packaging solution that was recyclable, aesthetically pleasing and effective. We developed a unique cartonboard structure using a customised grab-and-go variant of our ProducePack™ solution. The end result was a pack that met all of these aims, while achieving around a 15% reduction in defects due to bruising.

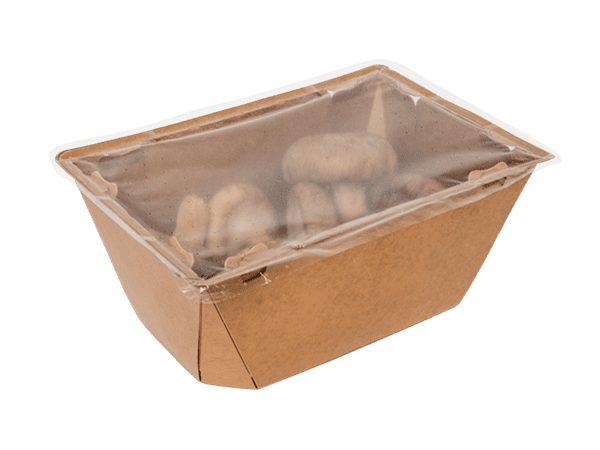

In cases where a hermetic seal is required – for example, in modified atmosphere packaging (MAP) solutions, commonly used for prepared fruit and salad applications – fibre-based solutions can achieve performance equivalent to – or better than – traditional plastic trays.

Hybrid solutions that combine a fibre-based tray with a minimal amount of plastic can achieve up to a 90% reduction in plastic, whilst providing the required barrier performance. PaperSeal™ is one such example.

Will moving to fibre-based packaging negatively impact my operations and supply chain efficiency?

Making the switch to more sustainable solutions doesn’t have to be a compromise. Graphic Packaging is an expert in easing the transition from plastic to paper with many tried, tested and trusted solutions already commercialised.

Our integrated machinery solutions are designed to minimise investment and disruption for converters. An example of this is the ProducePack™ Punnet, which is designed to run on standard forming machines.

By adopting sustainable fibre-based packaging now, produce growers, packers, brands and retailers can get ahead of the curve and prepare for a more circular future.