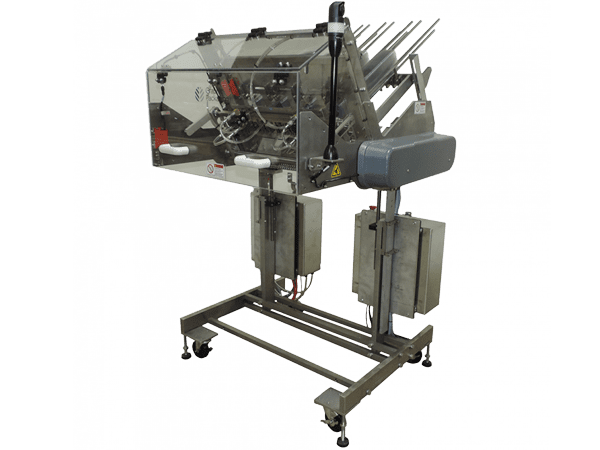

Tray Venting System

A mid-speed, intermittent motion, offline tray punching system for venting holes into plastic trays after thermoforming. The tray venting system is built to specification and is designed to handle a range of square or rectangular plastic trays.

Quick Links

Tray Venting System Features

Standard Features

- Dual-sided, 9” arm reciprocating vacuum placer for denesting trays

- Indexing flight conveyor for feeding the trays through the vent punching station

- Air cylinder powered, double-acting hole punching unit with tooling for each tray

- Specialized flight system to run different size and style trays with varying hole punch locations

Optional Features

- Two-head system to double the input of trays

- Dedicated faceplate style quick-change magazines for repeatable and reliable changeovers to maximize production

- Touchscreen operator interface

Related Machinery

Reciprocating Pick and Place Machines

A standalone, flexible, intermittent-motion machine designed for picking and placing a variety of stackable items at the front of a production line.