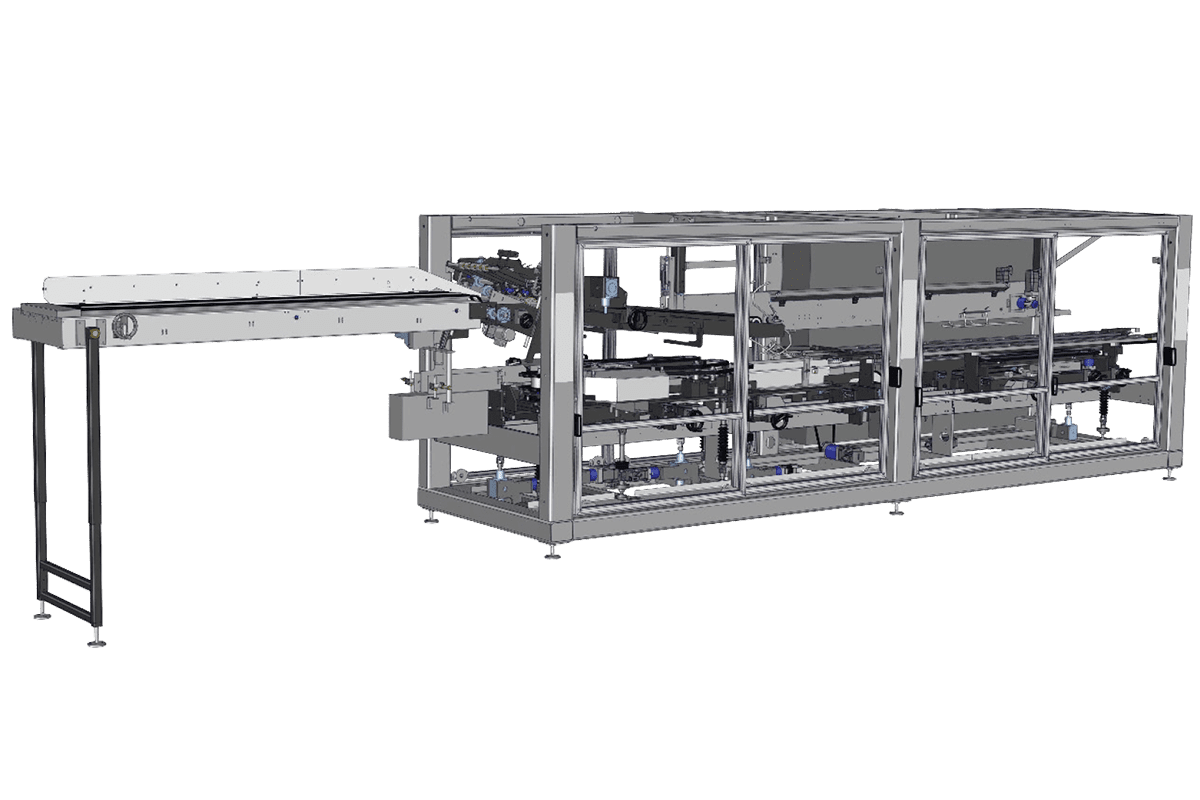

Marksman™ X5

The Marksman™ X5 is a family of high-speed, wrap-style multipack machines designed for glass and plastic bottles, and aluminum cans.

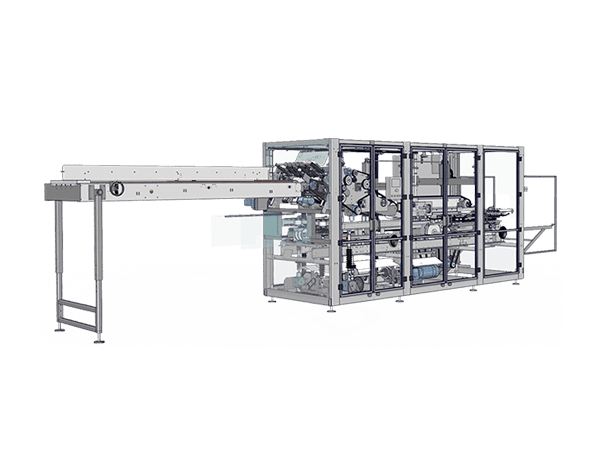

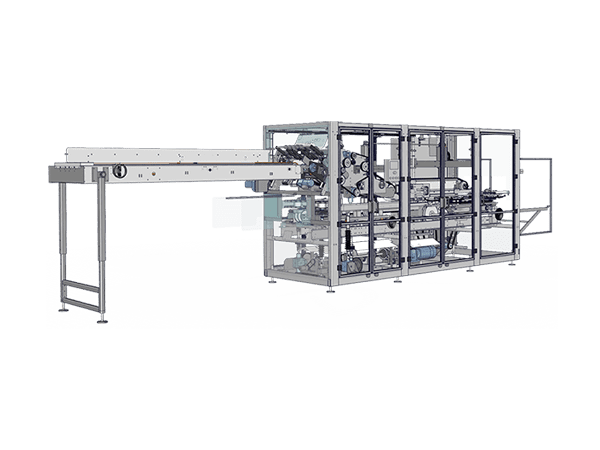

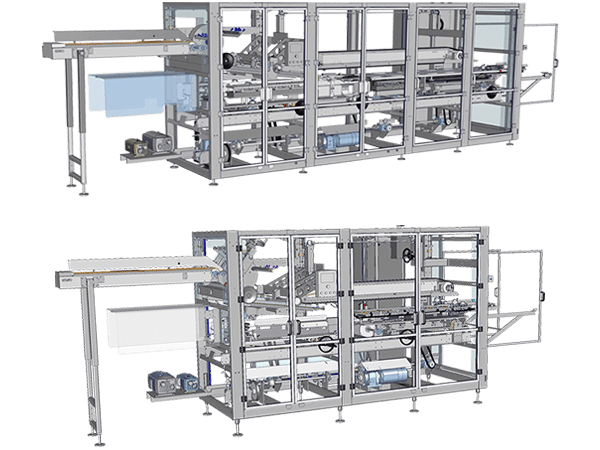

The Marksman X5 family includes:

- Marksman X5 LLF: With a low-level feeder, it provides optimal ergonomic carton loading on a 9 foot/3m feeder magazine

- Marksman X5 EPG: Adds the end panel glue unit, giving the ability to glue the pack and close the flaps on the end of the wrap, creating either a barcode cover or turning the pack into a fully enclosed carton

- Marksman X5 LFEG: Combines the ergonomic low-level feeder with the versatility of the end panel glue unit