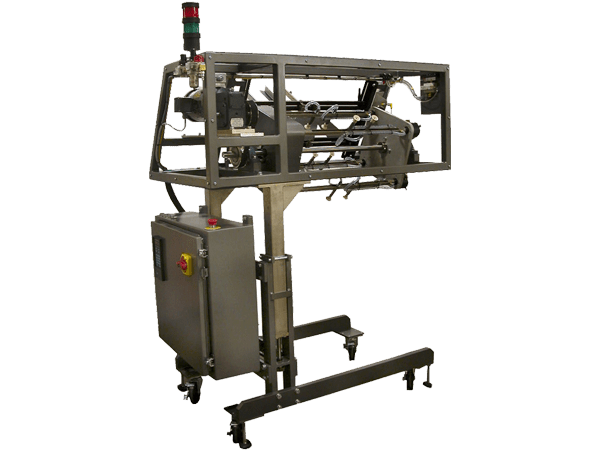

ElastiTag® Applicator

The ElastiTag® applicator is designed for the automatic application of Elastitag neck tags in a high-speed environment and accommodates a range of necked bottles and containers in a variety of sizes.

ElastiTag® is a registered trademark of Bedford Industries.

Quick Links

See the ElastiTag Applicator in Action

The ElastiTag applicator applies ElastiTag neck tags to bottles and containers automatically at high speed.

Related Machinery

Rotary Vacuum Placers

Rotary vacuum placers are flexible, continuous-motion machines designed for picking a variety of stackable items at high speed with placement onto or into another product on a conveyor or flight system.

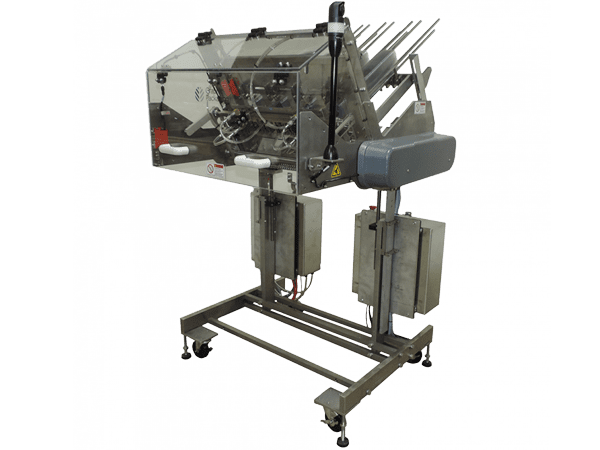

Reciprocating Pick and Place Machines

A standalone, flexible, intermittent-motion machine designed for picking and placing a variety of stackable items at the front of a production line.