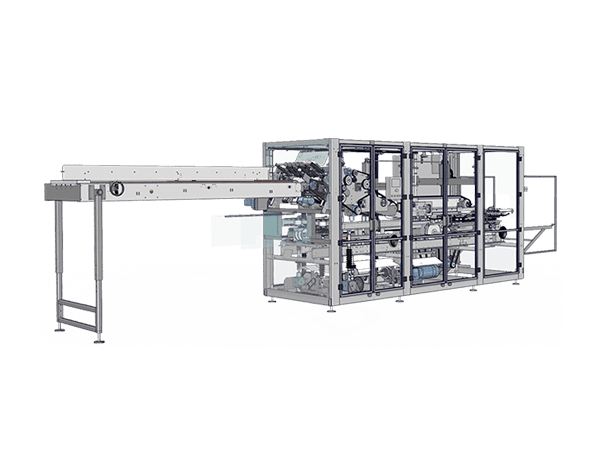

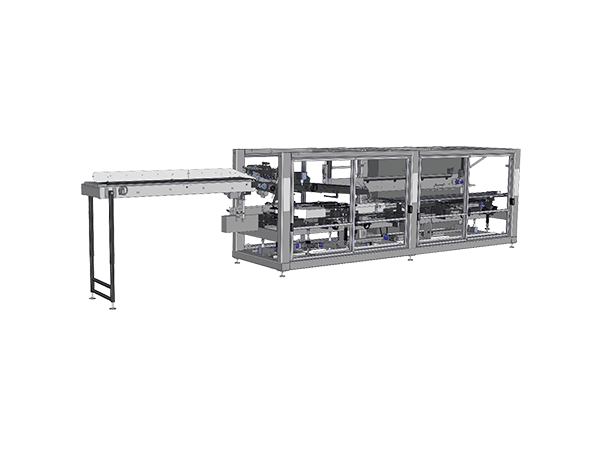

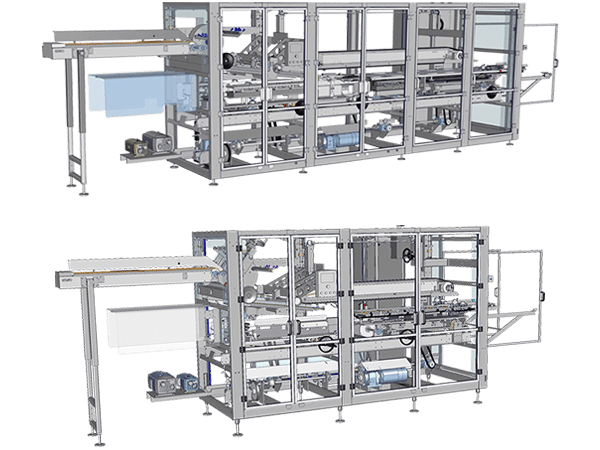

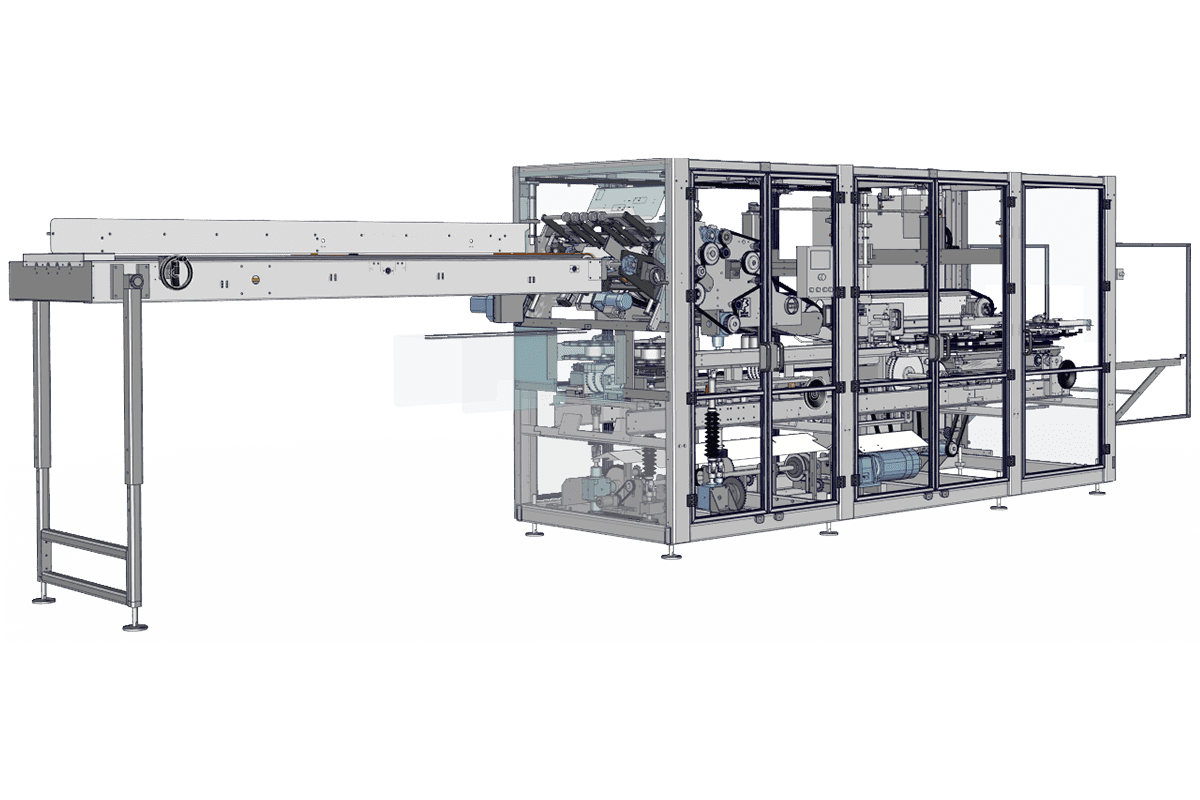

Marksman™ 750HS

The Marksman™ 750HS is a continuous motion, wrap-style multipack machine that is ideal for smaller multipacks of cans in 1×2, 1×3, 2×2, and 2×3 formats.

The base design is capable of running multiple can heights and diameters with appropriate change parts. Packs can include top and bottom gussets on dual-lane packs. The high-speed machine can apply 300 packs per minute and has a compact footprint.

The capabilities, flexibility, and performance of the Marksman 750HS provide improved efficiencies for can packaging.

Quick Links

Marksman 750 HS Features and Applications

Standard Features

- Standard lock

- Dual venturi vacuum generators

- Automatic oil and grease system

- 9 ft (3m) 5000 carton powered magazine

- Market-proven segment wheel feeder with optimized geometry

Applications

- Beer

- Craft beer

- Carbonated soft drinks

- Water and sports nutrition

- Coffee and tea

- Dairy

- Spirits and cocktails

- Wine

- Pet care