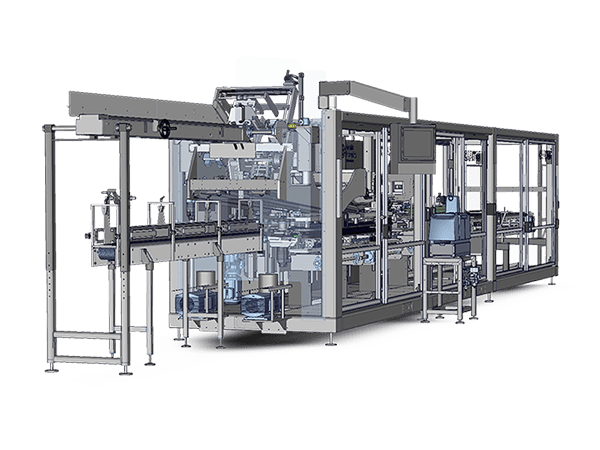

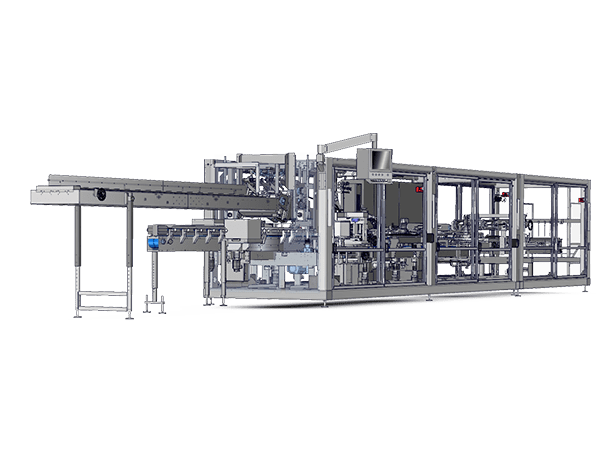

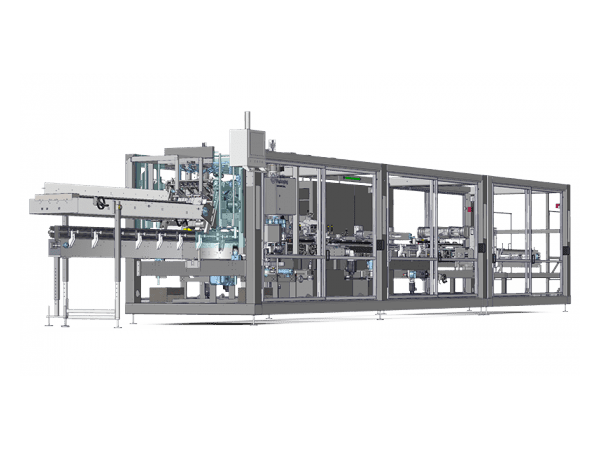

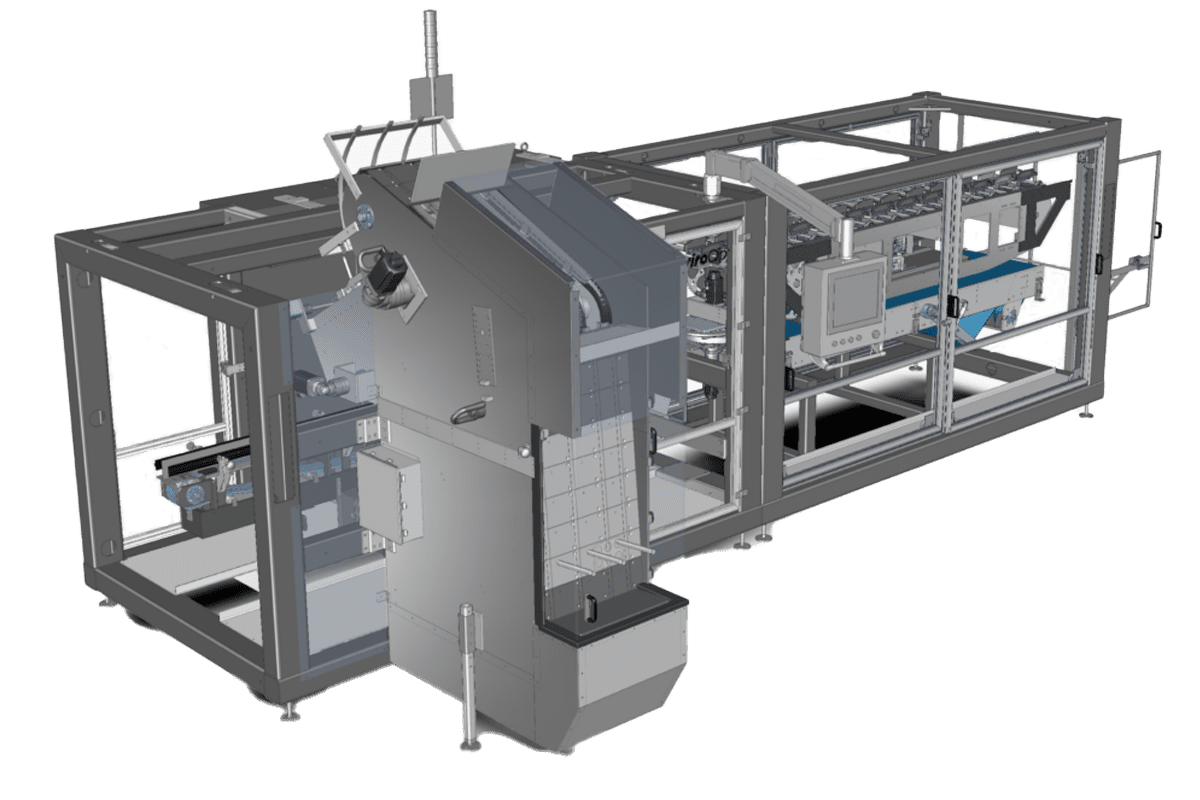

AutoClip™ ECR1800

The AutoClip™ ECR1800 is a high-speed beverage can clip packaging machine that incorporates proven product-pitched technology. The system runs the different multipack styles in the EnviroClip™ portfolio and is suitable for 66mm diameter beverage cans in four-, six-, and eight-pack formats.

The machinery system is efficient and easy to operate, can handle high-capacity carton magazines, and has a compact footprint that matches similar plastic ring solutions.

The AutoClip ECR1800 is an economical paperboard packaging solution that uses a minimal amount of material to provide an alternative to plastic rings and shrink wrap packaging. The machinery produces a single-ply pack with no glue or plastic laminations.

Quick Links

See the AutoClip ECR1800 in Action

The AutoClip ECR1800 is an economical paperboard packaging solution that uses a minimal amount of material to provide an alternative to plastic rings and shrink wrap packaging. The machinery produces a single-ply pack with no glue or plastic laminations.