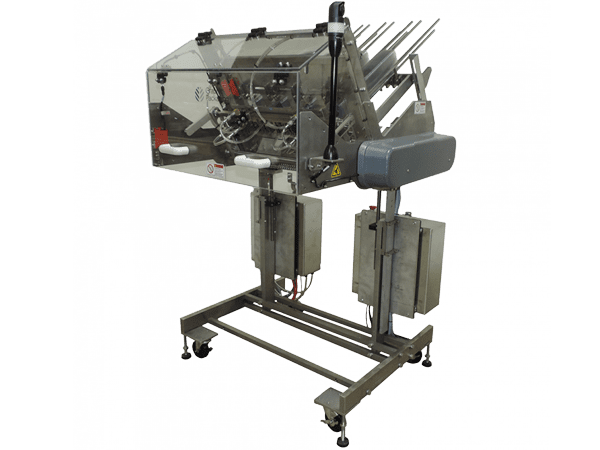

Rotary Vacuum Placers

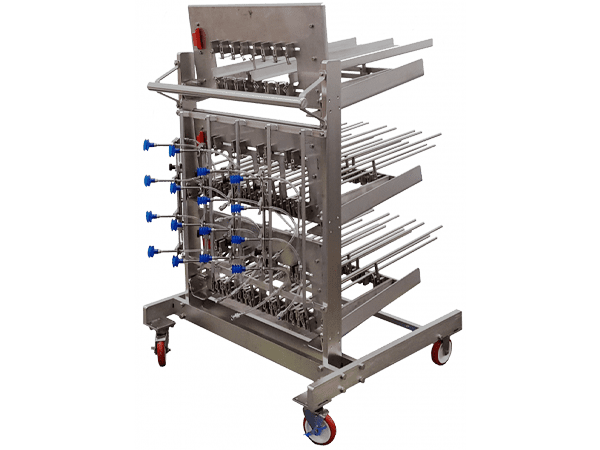

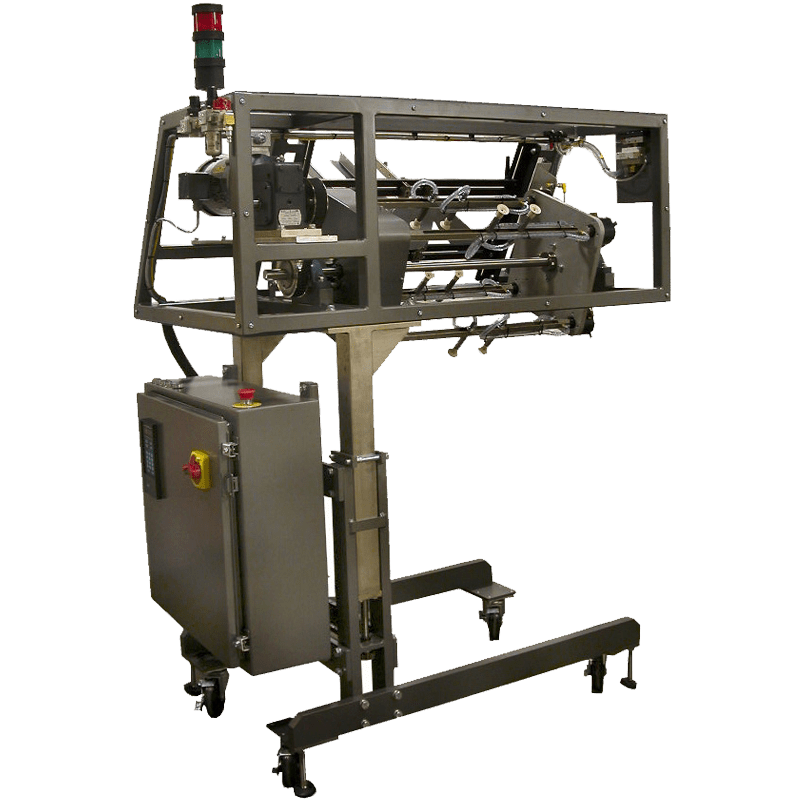

Rotary vacuum placers, also called rotary placers, onserters, or inserters, are flexible, continuous-motion machines designed for picking a variety of stackable items at high speed with placement onto or into another product on a conveyor or flight system.

They can work independently or be integrated with existing packaging lines to feed, denest, or erect product.

The rotary vacuum placer handles a variety of products such as cartons, paper carriers, CR80 cards, premiums, pizza sheets, and nested products such as bowls or tubs, lids, irregularly shaped products, pouches, and more.

Quick Links

See Rotary Vacuum Placers in Action

They can be standalone or integrated with existing packaging lines to feed, denest, or erect products.

“The equipment looks great, the accompanying documentation is top notch, and you have stayed within your time schedule. The new rotary feeder has performed very well for us. Our downtime for carton feeding has dropped to practically nothing.”

Major Home Products Company