Egg Carton Labeling Machine

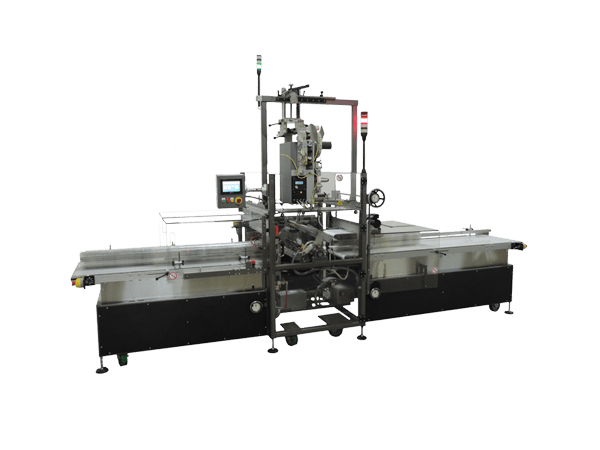

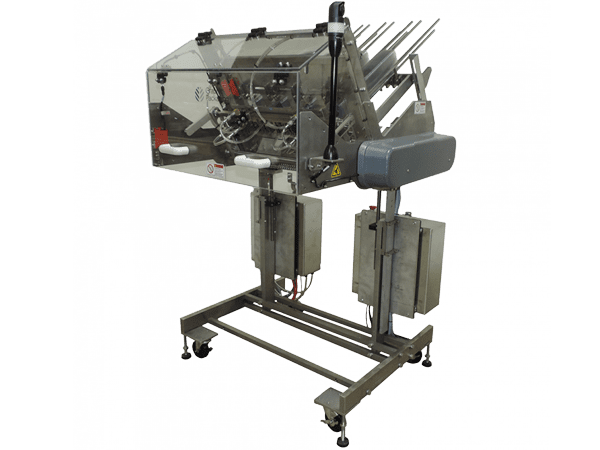

A flexible egg labeling machine designed for mid-speed application of paper labels onto plastic egg cartons, with the addition of tray counting and stacking.

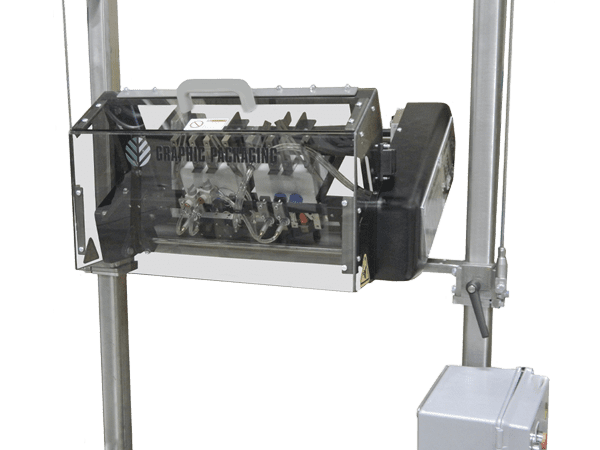

Available in a two-lane or three-lane configuration, our egg carton labeling machine is servo-driven with a Nordson ProBlue hot melt glue system to apply the labels.

Either model can produce these typical tray configurations:

- 12-count trifold, 12-count bifold

- 18-count bifold, 24-count bifold

Finishes, enhancements, and capabilities include:

- Two-lane machine: Aluminum frame

- Three-lane machine: Heavy-duty cold rolled steel frame with Steel-It epoxy coating

Quick Links

See the Egg Carton Labeling Machine in Action

A flexible egg labeling machine designed for the application of paper labels onto plastic egg cartons, with the addition of tray counting and stacking.