Press Releases

Graphic Packaging Launches Next-Generation Boardio™ Technology with Enhanced Multi-Footprint Capability

December 3, 2025

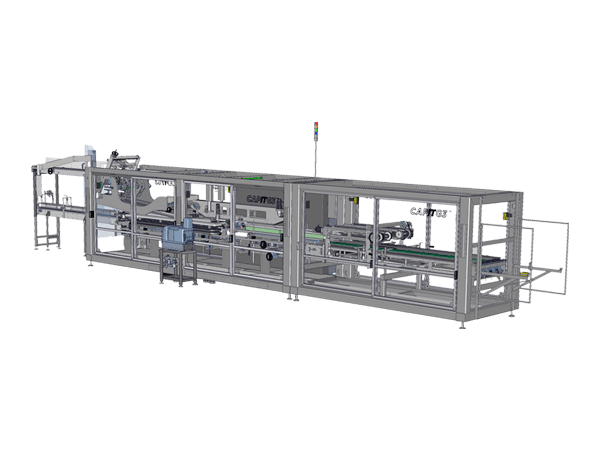

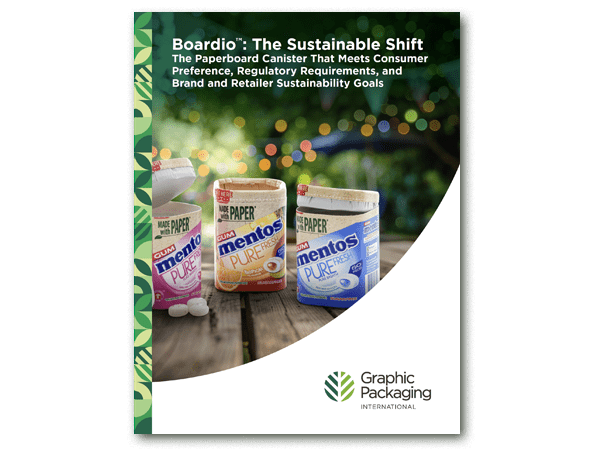

Graphic Packaging International (Graphic Packaging), a global leader in sustainable consumer packaging, has announced the launch of its next-generation Boardio™ machinery technology, offering enhanced multi-footprint capability that transforms how brands and co-packers approach Boardio paperboard canister production.

Brands and co-packers face mounting pressure to respond quickly to shifting market demands while maximizing their equipment investments. When capital is committed to packaging machinery, that investment needs to work harder, deliver more, and provide the flexibility to adapt as consumer preferences evolve, and the new Boardio machine multi-footprint capability does just that.

Boardio is a recyclable, rigid paperboard canister that provides an alternative to plastic, glass, and metal containers. Made from up to 90% renewable materials, it can deliver a plastic reduction of more than 90% versus rigid containers. Alongside winning 20 global packaging awards since launch, Boardio has replaced more than 50 million rigid plastic containers in 2023 and 2024 alone.

The Proven Boardio Platform, Now With Ultimate Flexibility

The new machine technology takes a proven platform and adds format flexibility through the addition of modules. The new multi-footprint capability enables Boardio production in multiple shapes — round, octagonal, triangular, and square — along with variable heights, widths, and barrier specifications, all from a single machine. Customers simply select modules based on the degree of flexibility they require.

For co-packers managing diverse client portfolios or large brands seeking to differentiate product lines and serve both large families and smaller households, this technology represents a significant operational and commercial advantage.

Johan Werme, head of sales for paperboard canister solutions at Graphic Packaging, said: “This new capability addresses a longstanding frustration customers have had with traditional packaging; rigid plastic and metal canisters typically lock brands into off-the-shelf formats unless they have the volumes to justify custom tooling. However, with Boardio’s new multi-footprint technology, we’re putting format control directly into the customer’s hands. That means shorter production runs across multiple configurations, the ability to iterate designs more frequently, and the transport and storage efficiency that comes from delivering canisters flat rather than pre-formed. It’s flexibility that scales with your business, not against it.”

For co-packers and brands alike, the technology ensures that capital investments in Boardio machinery deliver sustained value as market conditions shift, product portfolios expand, and the demand for more circular, more functional, and more convenient packaging solutions continues to grow.

The multi-footprint enhancement is now available as an option for new machine orders.

Related News & Events

explore

Additional Finishing Capabilities for Packaging

Additional finishing solutions for packaging include laser perforation of flexible materials to enhance shelf life or add other benefits, and advanced gluing solutions for more complex structural designs.

Quick Links

portfolio

Additional Finishing Capabilities Solutions

Complex Gluing Solutions for Packaging

Complex gluing applications can transform a flat blank into an attractive and innovative structure, helping to create on-shelf differentiation. Options include skiving and hemming, flame-sealing, CR adhesives, and more.

Laser Perforation

Incorporating laser perforation into flexible packaging can help to extend the shelf life of fresh food or can help to create features such as easy opening.

Related Finishes & Enhancements

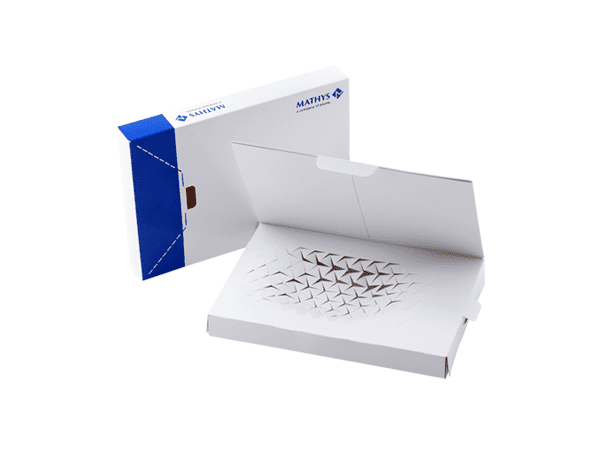

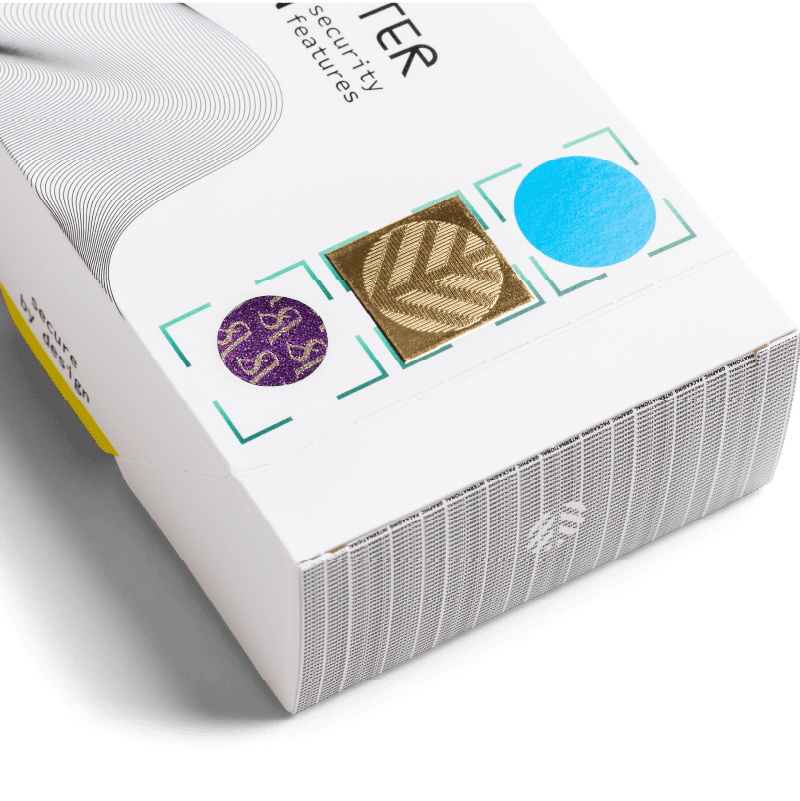

Anti-Counterfeit and Grey Market Coding Packaging Measures

Consumers expect authenticity when buying a premium product, and for the pharmaceutical industry the guarantee of authenticity is vital to maintain patient safety, but high-value markets are attractive to counterfeiters. Our state-of-the-art packaging solution can help prevent counterfeiting to ensure your brand integrity is maintained and patients are protected.

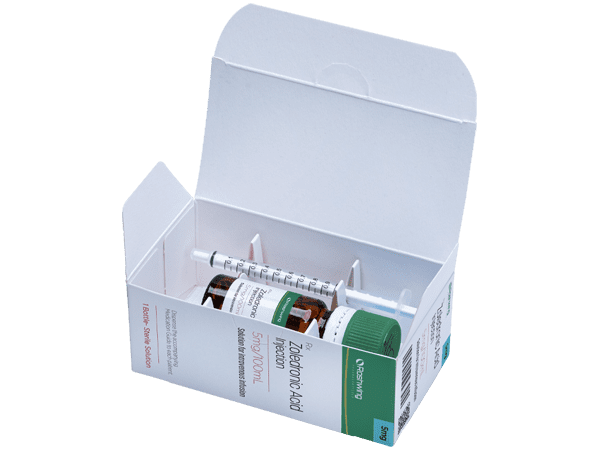

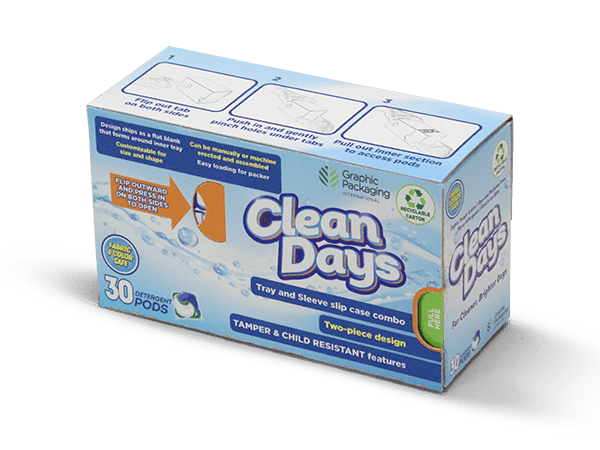

Child-Resistant Packaging

Often used for pharmaceuticals, medical devices, and other non-food consumer products, child-resistant packaging can protect children and vulnerable consumers from harm while still being intuitive and easy for those not at risk to open.

Tamper-Evident Packaging Measures

Tamper-evident packaging provides visible evidence to the end user that the product has not been tampered with. For pharmaceuticals, tamper-evident packaging is a requirement, while for other products it offers security throughout the supply chain and to the consumer.

Unilever Launches Next Generation Laundry Capsule Designed To Help Decarbonize Laundry, Save Energy and Cut Plastic Packaging

July 28, 2022

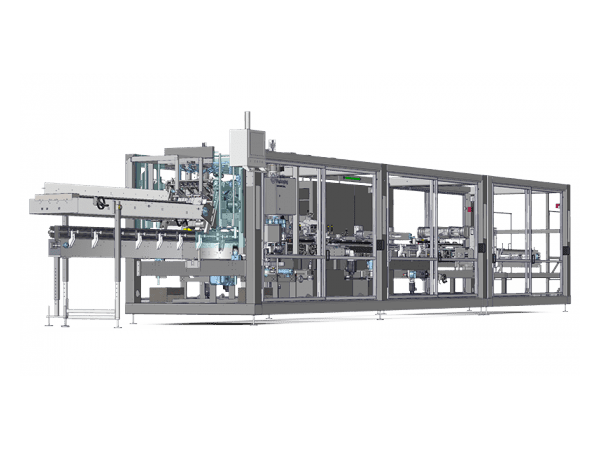

Unilever have announced the global launch of its most sustainable laundry capsule yet, the fastest growing detergent format in many parts of the world.

Unilever’s biggest laundry brand, Dirt Is Good (also known as Persil, Skip, OMO and Surf Excel), has introduced the newly designed capsule to help decarbonize the laundry process whilst delivering top cleaning performance. The new capsules are packaged in a plastic-free, paperboard container, a move set to prevent over 6,000 tonnes of plastic entering the waste stream every year, the equivalent in weight to 500 double-decker buses.

The specially designed formula contains biodegradable active ingredients that are 65% derived from plant sources and has been optimized to deliver top cleaning performance in cold and short cycles. The re-engineered capsule membrane is fully biodegradable and the fastest dissolving on the market, designed to leave no residue on laundry. The new capsule sees its carbon footprint reduced by 16 percent (vs. current capsules), and when used in cold, short cycles, consumers can save up to 60 percent energy per use.

The reduction in emissions across the products’ life cycle puts the new Unilever capsule at the forefront of efforts to decarbonize the laundry industry. This is an important step in reducing the Scope 3 GHG emissions of their laundry business, which includes those associated with consumers’ end use of our products, like the energy required to power washing machine.

For the first time ever, the laundry capsules will be packaged in a ground-breaking plastic-free paperboard box. The innovative box conceived in partnership with Graphic Packaging International, underwent years of development to lock out moisture better than current plastic packaging and prevent capsules from sticking to each other. The box is easier to open and close, is child-proof and fully recyclable. 50% of the cardboard comes from recycled sources and the rest from FSC-certified forests.

The new product, which will launch first in France before rolling out to other markets, is another example of Unilever’s Clean Future strategy. Announced in September 2020, the strategy aims to fundamentally change the way that some of the world’s best-known cleaning and laundry products are created, manufactured and packaged, supported by a €1bn investment over 10 years.

Dr. Keith Rutherford, Head of Global Innovation, Unilever Home Care R&D said: “Through our Clean Future program, our ambition is to make sustainable cleaning the compelling choice for every consumer by bringing real innovation to established mass market products. The research, development, and manufacturing skill that is required shouldn’t be underestimated. The new proprietary formulation and child-proof cardboard packaging is the work of so many people. This is our best and most sustainable laundry capsule yet – it is truly industry leading.”

Ralf Mack, Director New Business Development, EU Consumer Products at Graphic Packaging International adds: “Working together with Unilever, we are delighted to see our innovative packaging solution launch under this iconic brand around the world. Our combined expertise in carton design, product protection capabilities and understanding of consumer behavior has enabled us to create this superior, plastic-free and child-proof solution, enabling consumers and businesses alike to reduce their use of single-use plastic.”

Related News

CASE STUDY

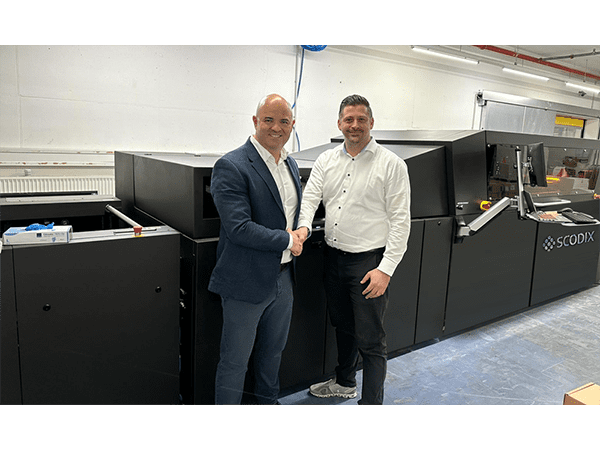

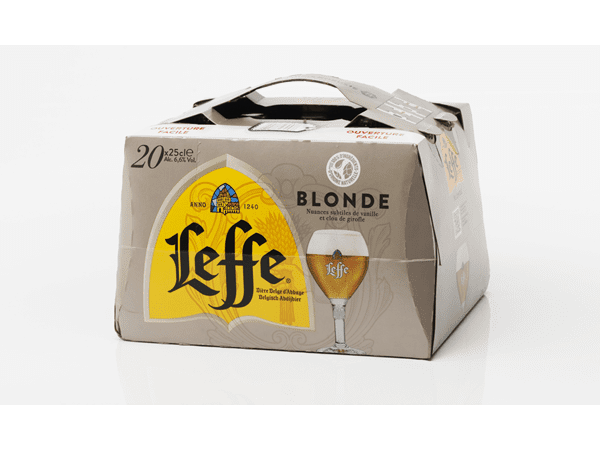

Devils Backbone Brewing Company Develops Foil-Stamped Basket Carrier to Capture Attention and Elevate Brand

CRAFT BEER | ELEVATED EXPERIENCE

Devils Backbone Brewing Company Establishes Their Prestige Series as a Luxury Beverage With Foil Stamping and Soft-Touch Coating

This basket carrier is a convenient solution with a custom profile and premium enhancements that captures consumers’ attention and elevates the brand. The foil-stamped basket carrier with soft-touch coating gives dimension and creates a unique tactile experience.

LET’S CONNECT

Contact Us

We strive to create unprecedented solutions that solve today’s real-life problems and pave the way for tomorrow’s biggest opportunities—in a feasible, cost-effective way.

Related Resources

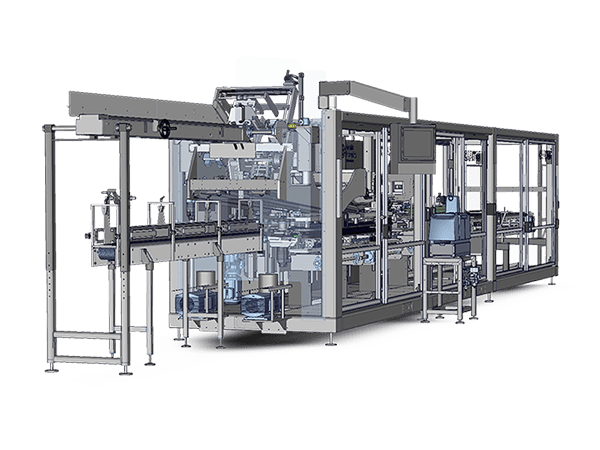

Cap-It™ Clip-Style Multipack Carton for PET Plastic Bottles

Cap-It™ is a recyclable paperboard clip solution for PET plastic bottles with neck rings. This multipack beverage packaging is an alternative to plastic rings and shrink film packaging.

Cap-It features an intelligent design that maintains pack integrity through the supply chain. On-shelf differentiation is achieved via a generous billboarding area, that still allows good visibility of the bottles.

Cap-It can be packaged with any of our Cap-It machinery equipment, including the Cap-It 2 and our new generation machine, AutoClip™ CIG3, that runs at higher speeds and provides enhanced bottle stability.

Quick Links

See Cap-It in Action

This intelligent carton design provides on-shelf differentiation by offering the opportunity to print high-impact graphics on the paperboard while leaving the bottle visible to the consumer.

Asahi Soft Drinks Launches Cap-It™, a Fully Recyclable Clip-Style Carton for PET Bottle Multipacks

Asahi Soft Drinks needed a new multipack solution

for their Wilkinson Sparkling Water range in

response to increased production volumes and

the shift from cans to PET bottles for soft drinks

Related Machinery

Related Finishes and Enhancements

Healthcare in 2026: Seven Forces Reshaping Demand

Healthcare in Europe and the UK is in a time of change. Digital tools, new regulations, an ageing population, evolving care models, tighter investment, and sustainability goals are reshaping how care is delivered and how products reach patients.

For businesses buying packaging at scale, this is no longer just about compliance or cost. Packaging is becoming part of the healthcare system itself: carrying data, protecting patients, supporting sustainability goals, and keeping complex supply chains running smoothly.

Read the article to discover seven key 2026 healthcare trends and the opportunities they present for healthcare packaging:

1. Digital Transformation Becomes Core Infrastructure

Artificial intelligence (AI) has developed into a core element of drug development, diagnosis, and patient triage. The European Health Data Space (EHDS) is making it easier to share health data across borders, while new “sandbox” programs let companies test AI safely under regulatory supervision. Fast Healthcare Interoperability Standards (FHIR) are becoming mandatory, not optional, allowing different health systems to communicate seamlessly. Trust sits at the heart of this transformation — and building it remains a critical challenge for healthcare systems globally.

For packaging, this accelerates the move from being a silent container to an active part of the digital journey. Unique codes, QR links, NFC tags, and digital patient leaflets are becoming standard. Smart packaging can confirm authenticity, monitor temperature, and support patients in taking medicines correctly. Security features that prevent tampering and counterfeiting are no longer “nice to have”; they’re essential in a world where physical products are tightly linked to digital records.

2. Regulatory Evolution: From Burden to Differentiator

Rules across Europe and the UK are tightening. Drug pricing faces pressure (influenced partly by the US Inflation Reduction Act), approvals are more closely watched, AI integration must meet new regulations, and companies must show clearer proof of safety, value, and environmental impact. After Brexit, the UK continues to follow its own path in some areas, while the EU has updated its pharmaceutical and medical device laws and strengthened sustainability reporting.

Packaging is where these rules become visible. Clear labelling, reliable traceability, tamper evidence, and the ability to quickly update information across countries are critical. Materials must be well-documented and easy to audit. Working with suppliers who understand these rules and respond quickly creates a competitive advantage and avoids costly delays.

3. Evolving Care Models: From Hospitals to Homes

Remote care has evolved beyond video appointments. Virtual hospitals now combine online consultations, remote monitoring, home testing, and digital prescriptions. Subscription care and direct-to-consumer health services are also expanding, bringing retail-like experiences into healthcare. This January saw the launch of ChatGPT Health, which allows users to connect medical records to AI assistants, while Anthropic introduced Claude for Healthcare with HIPAA-ready tools for providers, payers, and consumers.

The private prescription market is growing alongside these changes, with online pharmacies offering prescription medicines in countries like Germany and the UK, and cross-border electronic prescription systems expanding across Europe. Direct-to-patient e-commerce channels are showing the highest growth as patients embrace home delivery and digital convenience.

As healthcare moves faster, packaging must work as well in a kitchen as in a clinic. It needs to be easy to open, simple to understand, safe to dose, and robust enough to survive delivery networks. It should be designed look and feel trustworthy and medical-grade, even when sold through consumer channels.

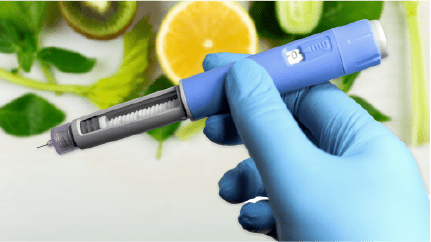

4. The Metabolic Health Revolution and GLP-1 Adjacencies

The adoption of GLP-1 therapies for weight loss and metabolic health is accelerating. These treatments are changing lives and reshaping entire markets. Food retailers, wellness brands, and subscription services are launching ranges designed to support people using these medicines: high-protein meals, portion-controlled packs, low-sugar snacks, and products aimed at gut health and fullness.

For pharmaceutical companies, this means packaging for injectables that feels discreet, reassuring, and high-quality, often with strict temperature control and smart monitoring. For nutrition brands, packaging must clearly explain benefits, portion size, and nutritional value while staying within regulations. Subscription-friendly formats, smaller pack sizes, and strong sustainability credentials win consumer trust in this fast-growing space.

5. Structural Drivers: Ageing, Chronic Disease, and Supply Chain Trust

The population of Europe and the UK is aging, with more people living with long-term conditions requiring ongoing treatment. New initiatives are accelerating the implementation of scientific innovations for diseases, and advanced therapies such as biologics and cell and gene treatments are becoming more common, bringing new handling and temperature-control challenges. Governments and health systems are also paying closer attention to where products come from and how secure supply chains really are.

Packaging must support long-term use, make life easier for older patients, and reduce medication errors. Features like easy-grip closures, larger text, and clear dosing instructions become essential. For complex treatments, packaging must provide excellent protection, clear traceability, and reliable cold-chain performance. Reusable shipping systems, anti-counterfeit features, and locally sourced materials help manage risk.

6. Market and Investment: Building for Sustainable Growth

After years of fast growth and big promises, healthcare investment is becoming more practical and disciplined. Money is flowing into areas that can scale safely and meet regulations with confidence, such as outpatient care, diagnostics, mental health, and specialist health technology. The UK government’s 10 Year Health Plan for England sets out an ambitious vision to transform the NHS through digital innovation, neighborhood-based care, and prevention — built to serve generations to come.

This puts pressure on packaging to deliver better value efficiently. Standardized formats that work across products and markets, packs that run smoothly on automated lines, and designs that reduce waste all matter. Buyers increasingly look at full cost over time, including recalls, delays, and disruptions, rather than the cheapest option on paper. Packaging that supports lean manufacturing and minimizes errors creates a real commercial advantage.

7. Sustainability as a License To Operate

Sustainability is no longer a branding exercise. The EU Packaging and Packaging Waste Regulation (PPWR), net zero commitments, retailer Scope 3 targets, and mandatory carbon reporting mean environmental performance is embedded in tender criteria and supplier qualification. Circularity, recyclability, material reduction, and transparency are commercial requirements.

This accelerates the shift towards simpler recyclable structures, lower-carbon materials, lighter packs, and reusable transport solutions. Digital tools showing where materials come from and how they can be recycled are gaining importance. A supplier’s sustainability capability now affects everything from regulatory approval to commercial partnerships.

Conclusion: Packaging As Healthcare Infrastructure

In 2026, healthcare in Europe and the UK will be shaped by digital connectivity, tighter rules, care moving closer to home, a focus on metabolic health, an ageing population, and strong sustainability goals. Across all of this, packaging plays a bigger role than ever.

It is no longer just a box or bottle. It’s a way to meet regulations, connect with digital systems, protect patients, support more circular choices, and keep supply chains running with confidence. For organizations buying packaging at scale, the opportunity is clear: treat packaging not as a cost to minimize, but as a vital part of building a safer, smarter, and more sustainable healthcare system.

References:

- ‘European Health Data Space Regulation (EHDS)’, European Commission

- Millie Sophie Stenmarck Korsgaard and Daniel Holth Larsen, (2025), ‘Why clinician and patient trust is critical for digital transformation in healthcare systems globally’, World Health Forum

- ‘Summary of Inflation Reduction Act Provisions related to renewable energy’, United States Environmental Protection Agency

- James Belcher, (2026), ‘Navigating the Future of Medical AI Regulation in the UK’, Med Tech Insights

- ‘Introducing ChatGPT Health’, (2026), ChatGPT

- ‘Transform healthcare from insight to action’, (2026), Claude

- Zoe Wood (2026) ’UK supermarkets go all out for ‘Jab-uary’ with food for those on weight-loss drugs’, Guardian

- ‘New European initiative seeks to accelerate timely Alzheimer’s disease diagnosis and treatment’ (2026), King’s College London

- ‘Fit for the future: 10 Year Health Plan for England’, (2025), gov.UK

Packaging is a tangible and highly visible product, and it’s understandable that people want to know where it comes from. But facts matter — and the facts show that the paperboard industry is not the driver of forest loss.

If anything, with responsible practices and expertise at the forefront, it’s part of the solution, keeping forests in active use, encouraging land stewardship, and maintaining critical carbon sinks.

To learn more about our “Better, Every Day” approach to sustainability, visit our sustainability area to explore our commitments in full.

Related Resources

Drink Different: The Bold Beverage Trends Taking Over 2026

As we enter 2026, the global beverage landscape is undergoing a profound transformation. The “viral” era of fleeting ads is being replaced by a more grounded, intentional approach to what we consume.

From the “Body OS” movement to the rise of nostalgia, here are the key trends defining how the world will drink this year.

The “Body OS” and Personalized Functionality

While protein was the undisputed king of 2024 and 2025, 2026 is officially the year of fiber. Driven by the mainstream rise of GLP-1 medications and a deepening understanding of gut health, consumers are treating their bodies like operating systems that require specific “upgrades.”

We are seeing a surge in “protein-ification” and “fiber-maxxing” across unexpected categories — think high-fiber cocktail mixers and probiotic-enriched pastas. The focus has shifted from “what to avoid” (sugar, gluten) to “what to add” (bioactive compounds, prebiotics, and adaptogens) to optimize daily performance and long-term longevity.

Consumers may also move on from specific goals of “maxxing,” or the viral advice to consume high amounts of protein or fiber each day, to adopt inclusive diets that celebrate the functional benefits of consuming a diverse variety of ingredients.

Protein Gains Traction in the Beverage Sector

The beverage sector will see the rising trend of “proteinization” with protein added to a wide range of drinks. Once limited to nutritional shakes, meal replacements, and fitness drinks, high/added protein claims are gaining traction across more drinks.

Ready-to-drink (RTD) coffee and flavored water will lead, with RTD tea and carbonated soft drinks following. This shift reflects consumers’ rising demand for convenient, enjoyable sources of protein (regardless of any “processing” that is necessary to fortify otherwise natural beverages). Improving protein taste is key to driving broader adoption. Just as RTD coffee successfully masks protein’s flavor, other beverages will leverage distinct taste profiles and textures like carbonation to make protein-rich options more appealing.

Eventually, to meet consumers’ evolving wellness priorities, high/added protein claims will become more mainstream in drinks, alongside gut health and immunity benefits.

Variety wins: Consumers are moving past “one‑nutrient” drinks. By 2030, they’ll look for flavor and ingredient diversity—think hibiscus, tamarind, barley tea, kefir, botanicals, and global fruit blends — making variety the new signal of a healthier beverage choice.

Gut health goes mainstream for families: Parents will seek kid‑friendly microbiome support in drinks: low‑sugar prebiotic juices, cultured dairy/kefir smoothies, and gentle, bacteria‑boosting options. Brands that teach “feeding good bacteria” and keep labels simple will win trust.

Fiber becomes everyday protection: Expect fiber‑forward formats — soluble‑fiber waters, fiber‑enriched smoothies and mixers — to be framed as daily defence for modern lifestyles, tapping emerging evidence on fiber’s role in offsetting environmental stressors.

Heritage Ingredients and a Desire for Nostalgia

Drinks rooted in nostalgia and trusted traditions help consumers feel more grounded in an increasingly volatile, tech‑driven world. As AI accelerates formulation, brands are rediscovering the power of tradition — brewing cascara like our grandparents did, layering botanical bitters from apothecary lore, and fermenting whey into lively sodas. The result is modern convenience built on heritage ingredients that consumers already trust.

For Gen Z, beverages are about more than taste — they’re about connection, place, and the stories behind each sip. UK Gen Z drinkers are especially drawn to culturally authentic spirits like Soltol. Meanwhile, artisanal, heritage‑inspired hot drinks are rising in popularity as consumers look for more than a quick caffeine fix; they want a meaningful, intentional start to their day.

The Rise of Zero-Alcohol Beverages

Once considered niche, zero-alcohol beverages have become a mainstream choice for consumers seeking wellness, moderation, and sophistication. Consumers are increasingly prioritizing physical and mental health. In fact, 40% of those choosing no-alcohol spirits cite a healthy lifestyle as their main motivation. Gen Z and Millennials are leading the charge, with alcohol consumption among Gen Z declining by 25% over the past four years.

The “sober curious” movement has evolved into a commercial powerhouse, redefining social occasions with concepts like “soft clubbing” and coffee-based happy hours.

Mocktails Gain Popularity, But Traditional Soft Drinks Are Still Winning

There is a growing market for sophisticated non-alcoholic drinks that mimic the experience and flavors of alcoholic beverages. Brands are innovating with alcohol-inspired flavors, premium packaging, and collaborations with bartenders to deliver elevated taste experiences. However, while mocktails and non-alcoholic versions of alcoholic drinks are gaining popularity, traditional soft drinks, sparkling water, and tea remain the most common alcohol substitutes, largely due to their accessibility and perceived value.

The premium price of alcohol-free alternatives to alcoholic drinks likely compels people to drink water and soda instead. Over half (52%) of US alcohol drinkers claim that non-alcoholic versions of alcoholic drinks are not worth the price. In the UK and Germany, usage declines among the less well-off.

Market Momentum:

- The global non-alcoholic beverage market is projected to surpass $157 billion by the end of 2026.

- No-alcohol alternatives (beer, wine, spirits, RTDs) are forecast to grow by 50% in volume between 2025 and 2030.

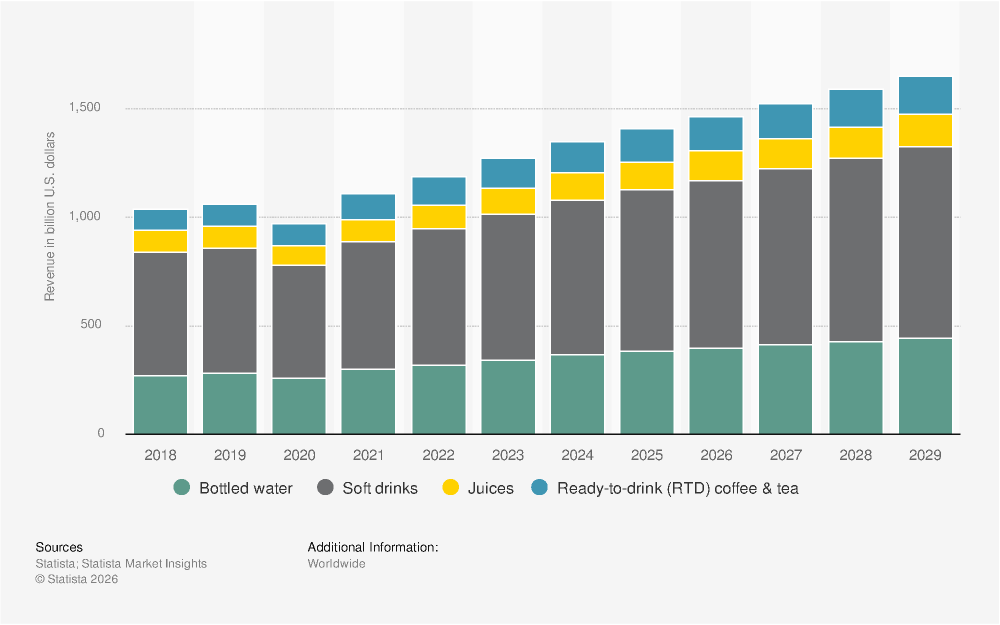

Revenue in the non-alcoholic drinks market worldwide from 2018 to 2029, by segment (in billion U.S. dollars)

Today’s zero-alcohol drinks go beyond “what’s missing” to deliver functional benefits and indulgent flavors. From adaptogen-infused sparkling teas to nostalgic dessert-inspired mocktails, brands are merging wellness with emotional connection. Functional beverages offering gut health, mood enhancement, and hydration optimization are booming, with the prebiotic soda market alone projected to reach $766 million by 2030.

- 92% of non-alcohol buyers also purchase alcoholic products, signaling that this trend is about choice and flexibility, not abstinence.

Flavor Trends to Watch

Non-alcoholic drink flavors are evolving into expressions of personal identity, cultural heritage , and holistic health. Flavor trends are also being shaped by mindful drinking, wellness-driven choices, bold taste profiles and the rise of viral flavors.

- 30% of US restaurant-goers want spicy flavors in non-alcoholic drinks.

- 100% of the wood fiber used in our paperboard manufacturing process is certified as sustainably sourced, and 96% of our facilities are certified to one or more fiber certification standards.

According to Mintel’s “Flavourscape AI”, emerging flavors include cream, cherry, punch, tropical, caramel, and passionfruit/maracuja. Declining flavors include cola, kombucha, cranberry, blueberry, coconut, and mint.

From “Sustainable” to “Circular”

The industry is shifting toward circular processing, where “waste” from one product becomes the hero ingredient of another. Consumers will gain respect for resourcefulness, which will once again make upcycling genuinely innovative thanks to products that offer new experiences.

Examples include:

- Coffee cherry husk (cascara) → teas & sparkling sodas: The fruit around the coffee bean brews into aromatic teas or lightly sparkling sodas with dried‑fruit notes.

- Fruit peel & zest → botanical tonics & bitters: Citrus peels and herb stems head into zero‑waste tonics, syrups, and bitters, elevating low/no‑alcohol choices.

- Cheesemaking whey → fermented sodas & protein waters: The liquid whey left from cheese or yogurt can be fermented into lively, lightly tangy sodas or clarified and blended to make clear protein waters, cutting sugar while adding functionality.

Sensory-First Experiences

Multisensory beverages are evolving from playful novelties to practical, memorable experiences tailored to diverse sensory needs. Brands are now strategically using color, texture, and aroma to enhance drinking and brand identity, driving competition and differentiation. Unexpected scents and textures are being used to energize and build anticipation.

Examples include:

- pH‑reactive “color‑shift” botanicals in RTD teas/lemonades: Butterfly‑pea‑flower or similar botanicals shift from blue to pink/purple with citrus. The visible transformation builds theater at first sip and signals freshness/fruit content (no extra sugar required).

- Dual‑phase or layered drinks: Clear‑over‑cloudy layers (e.g., clarified juice over a pulpy base) that consumers mix at the table; the visual “merge” moment doubles as a micro‑ritual and reinforces “made‑for‑me” positioning.

- Nitro cascade for coffee/tea and functional sodas: The waterfall micro‑bubble effect is a built‑in, repeatable spectacle that also softens perceived bitterness — useful for botanicals.

Advances in materials science and digital printing are also making packaging more interactive, with features like peelable snack layers, scent-enabled bottle reuse, audio prompts, and tactile designs inspired by beauty brands becoming more common.

References:

- Mintel. 2026 Global Food & Drink Predictions.

- CaterSource. (2026). A Taste of Tomorrow: The Trends That Will Rule 2026

- Mintel. (2025). Zero alcohol drinks and consumer-behavior

- Forbes. (2026)The rise of sober-curious Gen-Z

- Grand View Research. (2025) Industry Analysis Prebiotic Soda-Market Report

Packaging is a tangible and highly visible product, and it’s understandable that people want to know where it comes from. But facts matter — and the facts show that the paperboard industry is not the driver of forest loss.

If anything, with responsible practices and expertise at the forefront, it’s part of the solution, keeping forests in active use, encouraging land stewardship, and maintaining critical carbon sinks.

To learn more about our “Better, Every Day” approach to sustainability, visit our sustainability area to explore our commitments in full.

Related Resources

What’s Shaping the Way We Eat in 2026?

As we enter 2026, the global food landscape is undergoing a profound transformation. The “viral” era of fleeting ads is being replaced by a more grounded, intentional approach to what we consume.

From the “Body OS” movement to the surprising return of freezer-aisle fine dining, here are the key trends defining how the world will eat this year.

The “Body OS” and Personalized Functionality

While protein was the undisputed king of 2024 and 2025, 2026 is officially the year of fiber. Driven by the mainstream rise of GLP-1 medications and a deepening understanding of gut health, consumers are treating their bodies like operating systems that require specific “upgrades.”

We are seeing a surge in “protein-ification” and “fiber-maxxing” across unexpected categories — think high-fiber cocktail mixers and probiotic-enriched pastas. The focus has shifted from “what to avoid” (sugar, gluten) to “what to add” (bioactive compounds, prebiotics, and adaptogens) to optimize daily performance and long-term longevity.

Consumers may also move beyond specific goals of “maxxing,” or the viral advice to consume high amounts of protein or fiber each day, to adopt inclusive diets that celebrate the functional benefits of a diverse range of ingredients.

Consumers are looking for tasty snacks that improve the gut microbiome, reduce bloating, and provide a mental boost. Being tasty is key. Consumers want “good for you” fiber, probiotic, and adaptogenic snacks that look and taste like “bad for you” snacks.

Variety wins:

Consumers are moving past single‑nutrient fads. By 2030, they’ll expect food brands to champion diverse, culturally rich ingredients — making “variety” the new marker of healthy eating.

Gut health goes mainstream for families:

Parents will actively seek baby and kids’ products that support gut health. Brands that educate on the microbiome and offer bacteria‑boosting recipes will earn trust quickly.

Fiber becomes everyday protection:

With growing evidence around fiber’s ability to counter the effects of microplastics, fiber‑rich products will be positioned as simple, daily “protection” against modern lifestyle stressors.

Heritage Ingredients and a Desire for Nostalgia

Technology is paradoxically driving us back to our roots. As AI begins to dominate food R&D, it is driving a move toward heritage ingredients and ancient traditions.

Foods that evoke nostalgia and draw on trusted, time‑honored culinary traditions help consumers feel anchored amid an unpredictable, tech‑driven world. As people seek comfort and control, they’re increasingly turning to dishes and ingredients that reflect a simpler, idealized past.

By 2030, more brands will meet this need by reviving historic ingredients, classic preparation methods, and age‑old food wisdom. Convenient, modern formats will reinterpret traditional cooking to help consumers feel grounded in their daily lives.

For Gen Z, eating is more than sustenance — it’s about cultural connection, a sense of place, and the stories behind each meal. They are especially drawn to foods with authentic roots and meaningful heritage. At the same time, artisanal and craft‑inspired foods that celebrate “the old way of doing things” are gaining popularity, as consumers increasingly want meals that feel intentional rather than rushed.

From “Sustainable” to “Circular”

The industry is shifting toward circular processing, where “waste” from one product becomes the hero ingredient of another. Consumers will gain respect for resourcefulness, which will once again refresh upycling as genuinely innovative thanks to products that offer new experiences.

Examples include:

Juice “pomace” (apple, carrot, beet) → pectin, fiber crisps & colorants: The skins and pulp left after pressing turn into natural pectin for jams, crunchy inclusions for trail mixes, or vibrant natural colorants for baked goods—zero synthetic dyes, strong story.

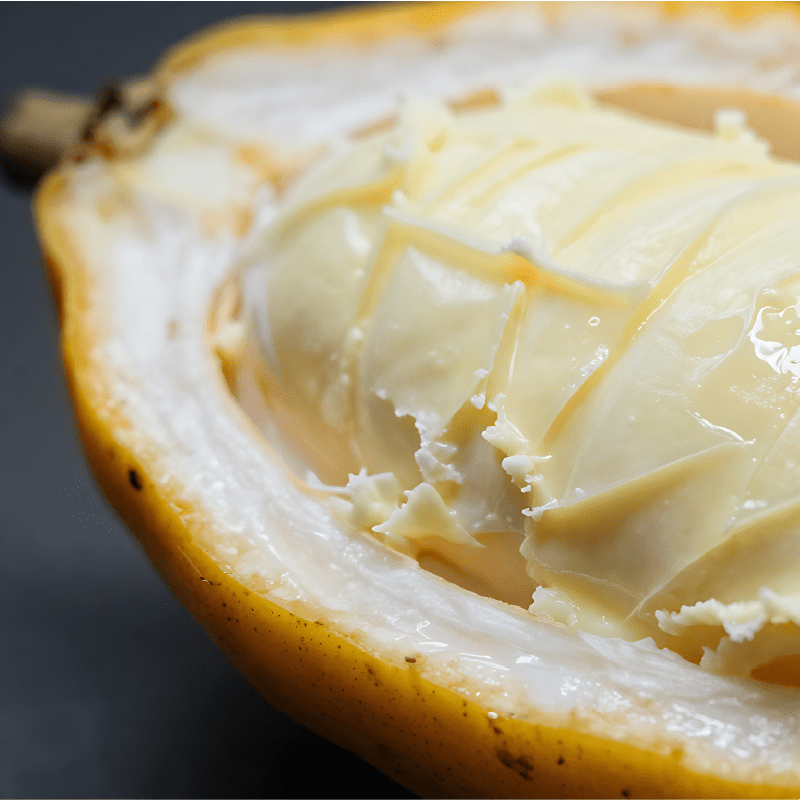

Cacao pulp (the white fruit around cocoa beans) → natural sweetener & frozen desserts: Usually discarded during chocolate processing, cacao pulp becomes a fruity syrup/sweetener or a sorbet base, adding tropical notes while lowering refined sugar.

Oat “pulp” from oat‑milk production → cookies & granola clusters: What’s left after filtration can be toasted and folded into bakes and snack clusters, adding fiber and a satisfying chew.

“Quiet Luxury” and Freezer Fine Dining

The economic “vibe shift” has birthed a new era of elevated comfort. Consumers are increasingly trading expensive nights out for high-quality experiences at home. This has revolutionized the frozen food aisle, once the domain of “TV dinners,” into a hub for freezer fine dining.

Expect to see Michelin-star collaborations in the frozen section, featuring gourmet flash-frozen techniques that preserve the integrity of premium ingredients like chanterelle mushrooms or slow-braised short ribs. This “quiet luxury” allows foodies to enjoy chef-quality meals at a fraction of the restaurant price.

Sensory-First Experiences

Food brands are moving beyond novelty to create purposeful sensory experiences that make eating more engaging and memorable. Color, texture, and aroma are being used more strategically than ever to elevate flavor perception, strengthen brand identity , and spark anticipation.

- The humanization of pet care is expanding the demand for multisensory treats designed for special moments, bringing the same attention to flavor, texture, and indulgence that we see in human food.

- For consumers using GLP‑1 medications, thoughtfully designed portions and visually appealing formats are helping restore the joy of eating by making each bite feel more intentional.

- Meanwhile, advances in materials science and digital printing are enabling next‑generation packaging — from peelable layers and scent-enabled reuse to tactile finishes and audio cues — transforming both food and pet products into richer, more interactive experiences.

References:

- Mintel 2026 Global Food Drink Predictions

- U.S. News & World Report – 2026 Health & Nutrition Trends

- SupplySide Food & Beverage Journal – 2025 Food Trends: Fiber’s Comeback

- Food & Wine: GLP-1 Medications Are Driving the Biggest Packaged-Food Shift in Years

- Innova Market Insights — Top Global Flavor Trends for 2026

Packaging is a tangible and highly visible product, and it’s understandable that people want to know where it comes from. But facts matter — and the facts show that the paperboard industry is not the driver of forest loss.

If anything, with responsible practices and expertise at the forefront, it’s part of the solution, keeping forests in active use, encouraging land stewardship, and maintaining critical carbon sinks.

To learn more about our “Better, Every Day” approach to sustainability, visit our sustainability area to explore our commitments in full.

Related Resources

Fresh Thinking for Food Packaging: Meet Us at Cfia Rennes

March 10 – 12, 2026

Join us at Cfia Rennes from March 10–12 at stand 11-C38, where we’ll be showcasing packaging innovations designed to help brands make the shift from conventional plastic to solutions that are more circular, more functional, and more convenient for both producers and consumers.

Our paperboard innovations for fresh and ambient food applications are engineered for operational efficiency, many running on existing packing lines, while delivering the standout shelf appeal shoppers love.

Backed by robust Design for Environment principles and expertise in navigating evolving regulatory requirements, we help customers achieve high-performance packaging that helps to reduce environmental impact while maintaining quality and a great consumer experience.

Join our team at stand 11-C38 to explore our latest food packaging innovations

Explore the PaperSeal™ Portfolio

The PaperSeal™ tray portfolio has a unique sealing flange that provides an excellent hermetic seal to ensure freshness. These modified atmosphere (MAP) and vacuum skin packaging (VSP) trays reduce plastic by 80-90 percent compared to traditional trays. They also offer enhanced recyclability to consumers, thanks to a range of barrier liners and top films that are recyclable according to CEFLEX guidelines.

Our latest innovation PaperSeal™ Pressed is a pressed paperboard tray capable of achieving a secure hermetic seal for modified atmosphere packaging applications. Designed for high-volume, price-sensitive applications such as pork, minced meat, and poultry, the cost-efficient production process makes PaperSeal Pressed a highly accessible alternative to plastic trays.

Discover Paperboard Sushi Trays and Cartons

Our paperboard sushi portfolio includes formats that meet the “plastic-free” definition according to the EU’s Single-Use Plastics Directive (SUPD) guidance, alongside solutions containing no plastic lamination or less than five percent plastic. All formats can be designed to be recyclable in household waste streams.

ProducePack Punnet Tray™

The ProducePack™ Punnet tray is a top-sealed paperboard punnet tray for cherry tomatoes, grapes, mushrooms, and berries, offering an alternative to traditional PP and APET punnets.

It is recyclable in household waste streams and can be classified as plastic-free according to the Single Use Plastic Directive definition if a fossil-based barrier coating is not required and when using plastic-free lidding films such as regenerated cellulose.

The punnet tray has been launched by a number of major European retailers, and has resulted in many millions of plastic trays being eliminated from their supply chains.

The intelligent design of the ProducePack Punnet tray makes it easy to switch between running plastic punnets and paperboard trays on the same packing line.

Boardio™ paperboard canister

With a unique shape and space for product information, Boardio™ is a paperboard canister offering excellent product protection and an opportunity for 360° branding on all six sides. Designed for a range of applications, including dry mixes, coffee, snacks, confectionery, nutrition powders, and more, Boardio is an alternative to rigid plastic, glass, and metal containers.

Multipack Cartons for Food, Pet Food, and Beverages

Our multipack carton portfolio for the beverage, food, and consumer products sectors is designed to accommodate a range of primary pack types, from cans to plastic and glass bottles and jars. The packs are designed to deliver impact on the retail shelf, drive consumer preference, and improve functionality at every touch point.

We offer a fully integrated approach to packaging and packaging machinery, with multipack applications ranging from soft drinks and beers to vegetables, dairy, pet food, and more.

Foodservice Packaging

Explore our portfolio of high-quality single-use food containers, cups, lids, and more, with great customization potential to ensure your brand shines. From quick-service restaurants to convenience stores and hotel chains, we provide the foodservice packaging solutions for the applications you need at the quality you demand.

Related News

News

Graphic Packaging CEO Robbert Rietbroek Appointed to American Forest and Paper Association

January 30, 2026

Left to right: Heidi Brock, president and CEO of the American Forest and Paper Association, and Robbert Rietbroek, president and CEO of Graphic Packaging International

Graphic Packaging International reaffirms its commitment to the sustainable consumer packaging industry through AF&PA membership.

The American Forest and Paper Association (AF&PA) welcomed a new class of leaders to its board of directors on Jan. 29. Robbert Rietbroek, president and CEO at Graphic Packaging International, was appointed to join the industry association that is elevating the voice of the U.S. paper and packaging industry and will shape the next era of sustainable forest products.

“We are pleased to welcome Robbert to the AF&PA Board,” said Heidi Brock, president and CEO of the AF&PA. “His contributions will be an asset as our advocacy efforts continue prioritizing policies that enhance industry competitiveness and sustainability. We appreciate him stepping into this important role.”

Graphic Packaging has been a member of the AF&PA since September 2007. Rietbroek will continue its longstanding role in amplifying this unified industry voice.

“Joining the AF&PA Board of Directors, I’m looking forward to advancing the issues important to our industry and the communities we serve,” said Robbert Rietbroek, President and CEO of Graphic Packaging. “We are advocating for practical solutions – improving recycling outcomes, strengthening sustainable forestry, and keeping U.S. manufacturing competitive – while continuing to innovate for our customers.”

Overview of AF&PA

The U.S. forest products industry manufactures essential, everyday products — such as paperboard packaging — from renewable resources. AF&PA helps this industry grow by advocating for public policies that:

- Advance sustainable industry practices

- Improve recycling of paper-based products

- Strengthen U.S. forest sustainability and resiliency

- Help transition the industry to renewable energy

- Support industry competitiveness

- Promote workforce safety

AF&PA members are “the most trusted voice for essential U.S. pulp, paper, packaging and wood products manufacturers in our circular economy,” according to the organization’s website. These leaders represent about 87% of U.S. pulp, paper, paper-based packaging and tissue production capacity in the United States.

Shaping the Paper and Packaging Industry

Trade associations like AF&PA are powerful outlets for influencing and staying abreast of emerging packaging trends, regulatory developments and customer needs. As an AF&PA member, Graphic Packaging:

- Helps improve paper cup recycling acceptance. Graphic Packaging is collaborating with AF&PA and other industry groups to increase U.S. community access and recovery rates for paperboard and paper-based packaging materials.

- Provides input on evolving packaging laws and regulations. Teams provide the company’s perspective and comments on changes that could impact employees, customers, suppliers and communities.

- Supports industry-wide sustainability and safety commitments. AF&PA members’ collective commitments demonstrate the industry’s importance in the circular economy.

- Collects innovation insights. These interactions supplement consumer research and customer feedback to inform the packaging innovation process at Graphic Packaging.

- Verifies recycling criteria for paperboard packaging. AF&PA’s design guidance for recyclability helps teams evaluate the technical recyclability of products.

The AF&PA is one of many industry associations Graphic Packaging supports to advance circular packaging.

Read more about Graphic Packaging’s advocacy efforts in the 2024 Impact Report.