ClipCombo™ for Cans

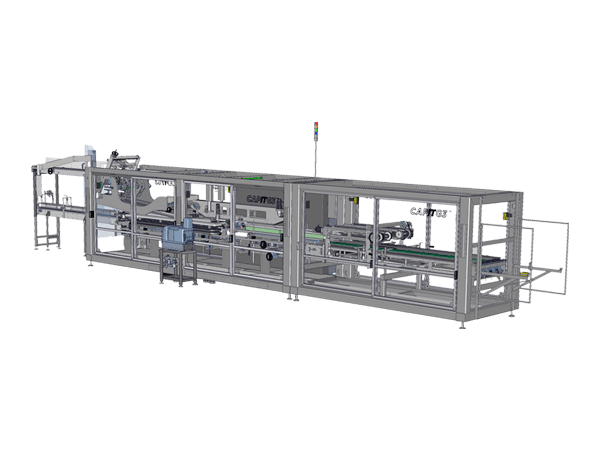

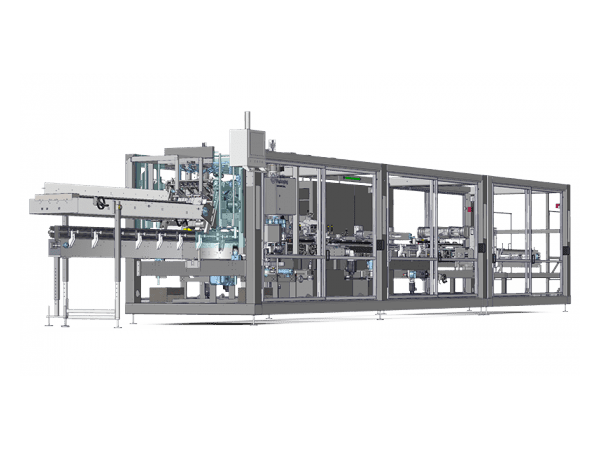

A highly innovative machinery approach to beverage packaging, ClipCombo™ for cans offers beverage makers the ability to run multiple paperboard canned multipack styles across the same machine, delivering real value and flexibility to meet today’s and tomorrow’s needs.

A proven technology concept, ClipCombo runs at high speeds no matter the style of pack being run, with easy, quick, tool-free changeovers. It combines premium and standard clip-style multipacks for cans in one flexible machinery solution. For example, combine KeelClip™ with EnviroClip™, or GripClip™ with EnviroClip for the ultimate packaging solution for can multipacks.

Applications include:

- Beer

- Craft beer

- Carbonated soft drinks

- Water and sports nutrition

- Coffee and tea

- Dairy

- Spirits and cocktails

- Wine

- Pet care

Quick Links

See ClipCombo for Cans in Action

ClipCombo for cans combines premium and standard clip-style multipacks for cans in one flexible machinery solution. For example, combine KeelClip with EnviroClip, or GripClip with EnviroClip for the ultimate sustainable packaging solution for can multipacks.

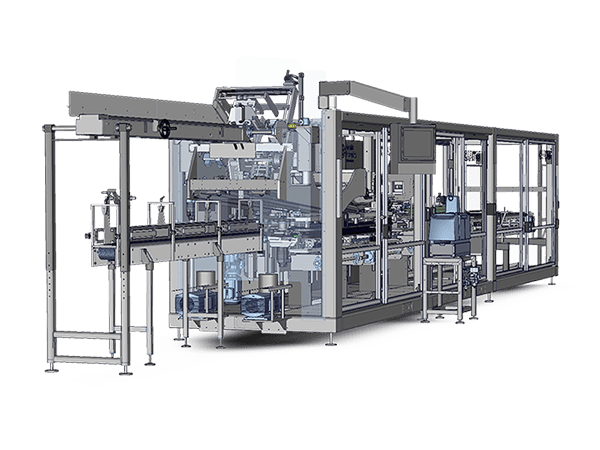

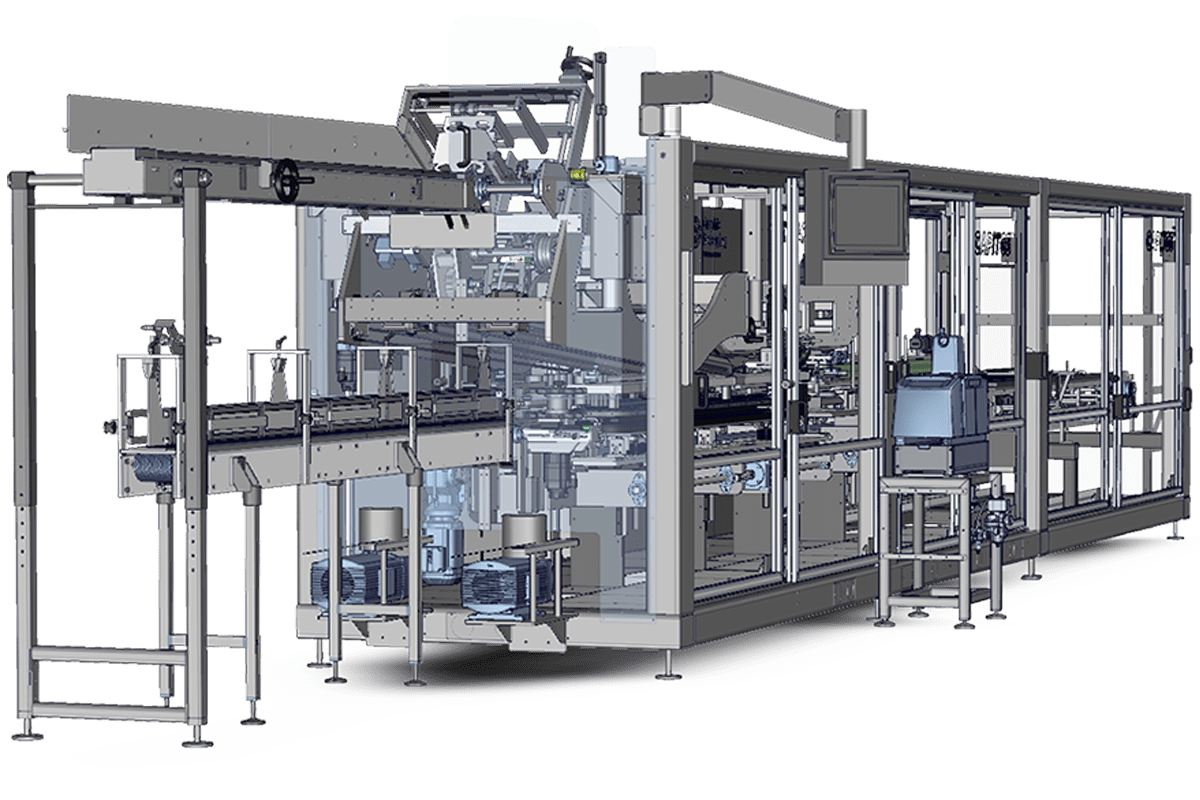

ClipCombo for Cans Features

EnviroClip

- Product pitched can transport belts

- Secondary motion rotary clip feeder

- Side transfer paper feed into a product belt

- Change part nick breakers for 4-,6-,and 8- packs

- Unique clipping belt system

- Servo main drive motors

- 15” color touchscreen

- Automatic prime and clean-out features

- Internal colored LED lighting

KeelClip or GripClip

- Product orientation turrets, one per lane to orient cans

- Integrated turner divider reject system

- Glue detection

- 10ft (3.2m) standard magazine

- Approx. 4500 carton capacity

- 10ft (3m) laned product infeed conveyor

- Segment wheel feeder

- IQ tablet with changeover checklist with videos and complete parts manual

- 15” color touchscreen in rolling HMI enclosure

Related Machinery

Related Products

KeelClip™ Clip-Style Multipack Carton for Cans

KeelClip™ is a paperboard clip-style multipack solution that replaces plastic rings and shrink film. It provides an enhanced user experience, great merchandising appeal and has an integrated high-speed machinery solution.

GripClip™ Clip-Style Multipack Carton for Cans

GripClip™ is a clip-style multipack for canned beverages and food items. It is a part of our can clip portfolio and is a sustainable alternative to plastic rings and shrink wrap.

EnviroClip™ Cans Clip-Style Multipack Carton

EnviroClip™ Cans is a clip-style multipack solution for canned beverages that uses Z-Flute™, a solid fiber design that adds strategic reinforcement where needed to deliver a strong clip that performs in both cold and humid conditions.