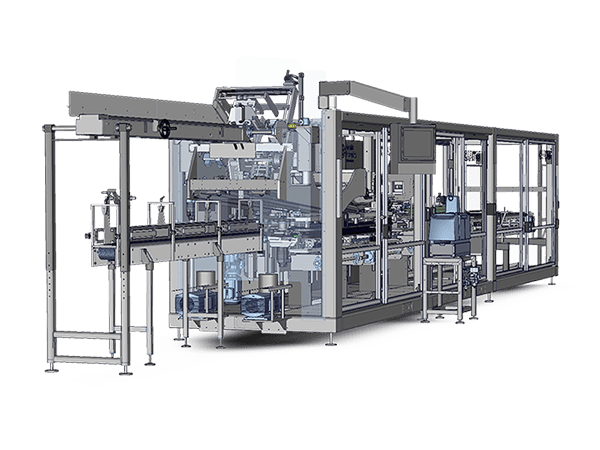

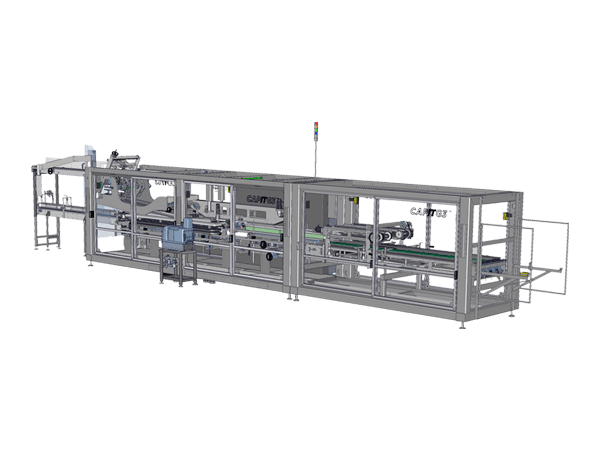

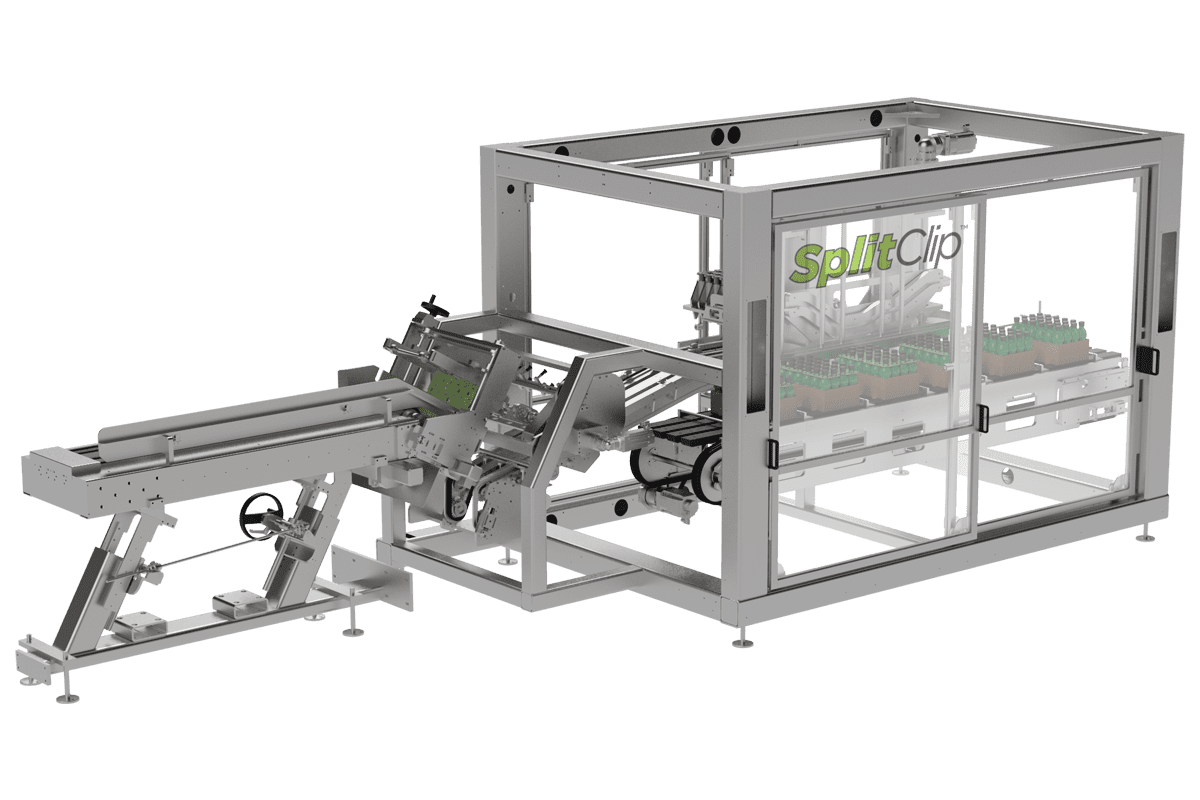

AutoClip SplitClip™

The AutoClip SplitClip™ is a continuous-motion machine that applies our EnviroClip™ clip-style carton to PET bottles already in trays in a single clipping application.

The 4 x 6 clip can be separated into the final format or left connected for pallet stability.

The machine can accommodate 4-, 6- and 8-pack configurations.

The product runs wide side leading, back-to-back through the machine for the lowest linear speed and fewest transfers.

Quick Links

Related Machinery

Related Products

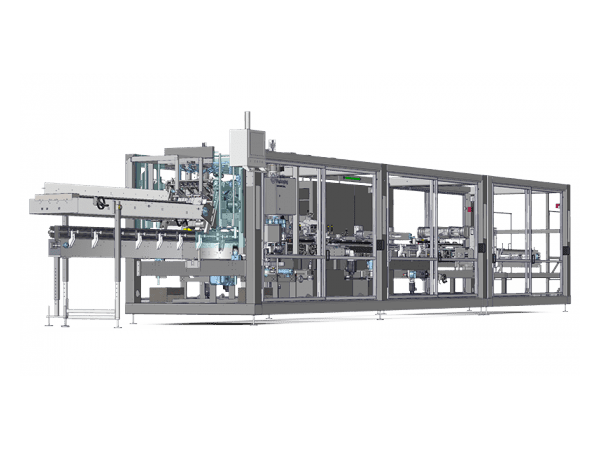

EnviroClip™ Beam Clip-Style Multipack Carton for PET Plastic Bottles

An alternative to plastic rings and shrink film, EnviroClip™ Beam is a paperboard clip-style multipack carton for PET bottles that uses minimal material and no glue.

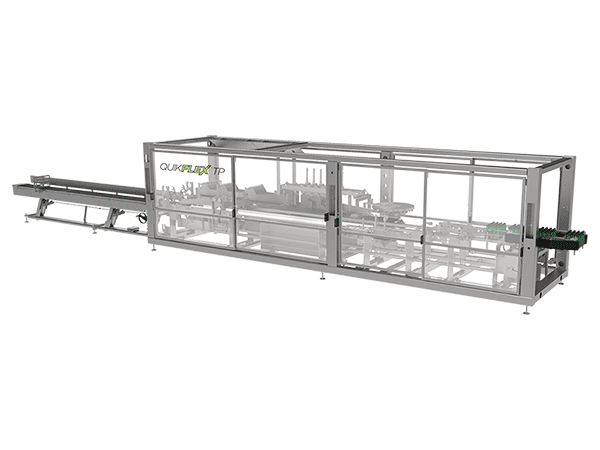

EnviroClip™ Duo for Multipacks of Plastic and Glass Bottles and Jars

EnviroClip™ Duo is a clip-style multipack solution for multipacks of glass and plastic bottles and jars.