explore

Additional Finishing Capabilities for Packaging

Additional finishing solutions for packaging include laser perforation of flexible materials to enhance shelf life or add other benefits, and advanced gluing solutions for more complex structural designs.

Quick Links

portfolio

Additional Finishing Capabilities Solutions

Complex Gluing Solutions for Packaging

Complex gluing applications can transform a flat blank into an attractive and innovative structure, helping to create on-shelf differentiation. Options include skiving and hemming, flame-sealing, CR adhesives, and more.

Laser Perforation

Incorporating laser perforation into flexible packaging can help to extend the shelf life of fresh food or can help to create features such as easy opening.

Related Finishes & Enhancements

Anti-Counterfeit and Grey Market Coding Packaging Measures

Consumers expect authenticity when buying a premium product, and for the pharmaceutical industry the guarantee of authenticity is vital to maintain patient safety, but high-value markets are attractive to counterfeiters. Our state-of-the-art packaging solution can help prevent counterfeiting to ensure your brand integrity is maintained and patients are protected.

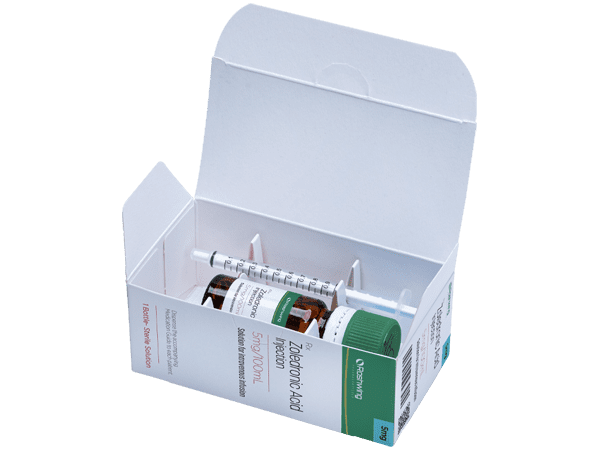

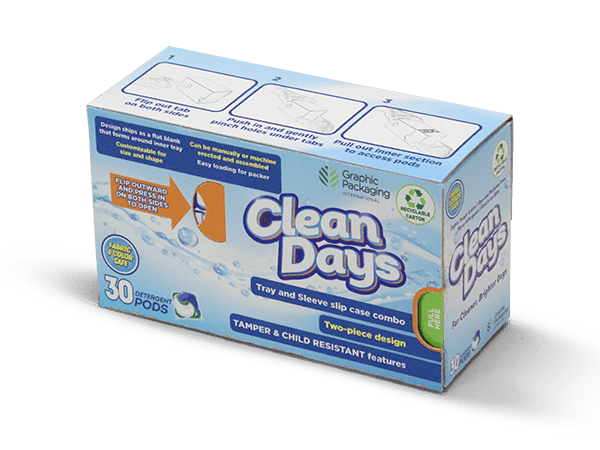

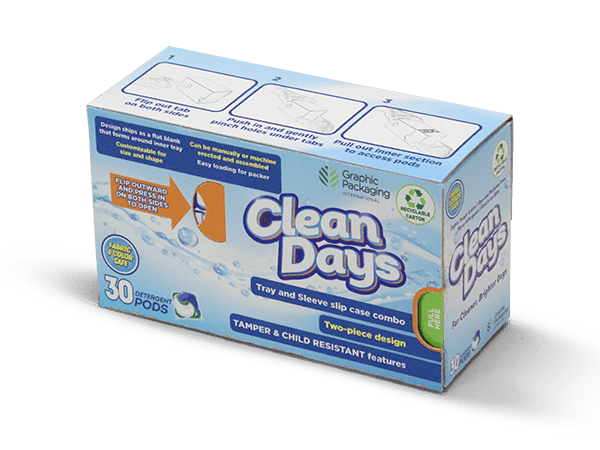

Child-Resistant Packaging

Often used for pharmaceuticals, medical devices, and other non-food consumer products, child-resistant packaging can protect children and vulnerable consumers from harm while still being intuitive and easy for those not at risk to open.

Tamper-Evident Packaging Measures

Tamper-evident packaging provides visible evidence to the end user that the product has not been tampered with. For pharmaceuticals, tamper-evident packaging is a requirement, while for other products it offers security throughout the supply chain and to the consumer.

Unilever Launches Next Generation Laundry Capsule Designed To Help Decarbonize Laundry, Save Energy and Cut Plastic Packaging

July 28, 2022

Unilever have announced the global launch of its most sustainable laundry capsule yet, the fastest growing detergent format in many parts of the world.

Unilever’s biggest laundry brand, Dirt Is Good (also known as Persil, Skip, OMO and Surf Excel), has introduced the newly designed capsule to help decarbonize the laundry process whilst delivering top cleaning performance. The new capsules are packaged in a plastic-free, paperboard container, a move set to prevent over 6,000 tonnes of plastic entering the waste stream every year, the equivalent in weight to 500 double-decker buses.

The specially designed formula contains biodegradable active ingredients that are 65% derived from plant sources and has been optimized to deliver top cleaning performance in cold and short cycles. The re-engineered capsule membrane is fully biodegradable and the fastest dissolving on the market, designed to leave no residue on laundry. The new capsule sees its carbon footprint reduced by 16 percent (vs. current capsules), and when used in cold, short cycles, consumers can save up to 60 percent energy per use.

The reduction in emissions across the products’ life cycle puts the new Unilever capsule at the forefront of efforts to decarbonize the laundry industry. This is an important step in reducing the Scope 3 GHG emissions of their laundry business, which includes those associated with consumers’ end use of our products, like the energy required to power washing machine.

For the first time ever, the laundry capsules will be packaged in a ground-breaking plastic-free paperboard box. The innovative box conceived in partnership with Graphic Packaging International, underwent years of development to lock out moisture better than current plastic packaging and prevent capsules from sticking to each other. The box is easier to open and close, is child-proof and fully recyclable. 50% of the cardboard comes from recycled sources and the rest from FSC-certified forests.

The new product, which will launch first in France before rolling out to other markets, is another example of Unilever’s Clean Future strategy. Announced in September 2020, the strategy aims to fundamentally change the way that some of the world’s best-known cleaning and laundry products are created, manufactured and packaged, supported by a €1bn investment over 10 years.

Dr. Keith Rutherford, Head of Global Innovation, Unilever Home Care R&D said: “Through our Clean Future program, our ambition is to make sustainable cleaning the compelling choice for every consumer by bringing real innovation to established mass market products. The research, development, and manufacturing skill that is required shouldn’t be underestimated. The new proprietary formulation and child-proof cardboard packaging is the work of so many people. This is our best and most sustainable laundry capsule yet – it is truly industry leading.”

Ralf Mack, Director New Business Development, EU Consumer Products at Graphic Packaging International adds: “Working together with Unilever, we are delighted to see our innovative packaging solution launch under this iconic brand around the world. Our combined expertise in carton design, product protection capabilities and understanding of consumer behavior has enabled us to create this superior, plastic-free and child-proof solution, enabling consumers and businesses alike to reduce their use of single-use plastic.”

Related News

CASE STUDY

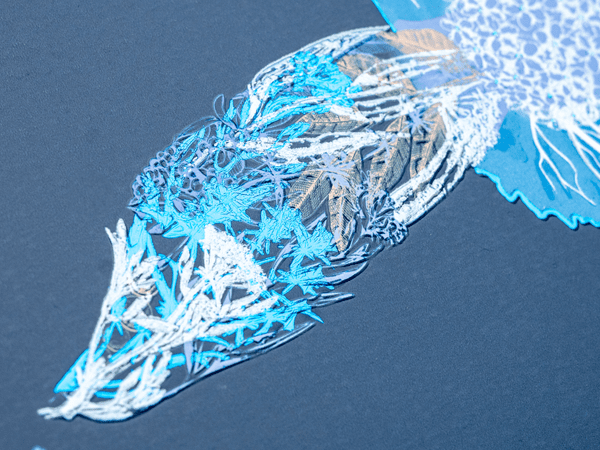

Devils Backbone Brewing Company Develops Foil-Stamped Basket Carrier to Capture Attention and Elevate Brand

CRAFT BEER | ELEVATED EXPERIENCE

Devils Backbone Brewing Company Establishes Their Prestige Series as a Luxury Beverage With Foil Stamping and Soft-Touch Coating

This basket carrier is a convenient solution with a custom profile and premium enhancements that captures consumers’ attention and elevates the brand. The foil-stamped basket carrier with soft-touch coating gives dimension and creates a unique tactile experience.

LET’S CONNECT

Contact Us

We strive to create unprecedented solutions that solve today’s real-life problems and pave the way for tomorrow’s biggest opportunities—in a feasible, cost-effective way.

Related Resources

CASE STUDY

Asahi Soft Drinks Launches Cap-It™, a Recyclable Clip-Style Carton for PET Bottle Multipacks

CARBONATED SOFT DRINKS | INNOVATION

Asahi Soft Drinks Launches Cap-It™

We are experienced in providing automated paperboard packaging at scale. For Asahi Soft Drinks, this meant the efficient transition away from manual packaging to an automated Cap-It system. The new pack style was successfully launched for the Wilkinson brand and expanded to other products, including carbonated items. Using the Cap-it machine for production, the client succeeded in reducing manual labor and costs.

LET’S CONNECT

Contact Us

We strive to create unprecedented solutions that solve today’s real-life problems and pave the way for tomorrow’s biggest opportunities—in a feasible, cost-effective way.

Related Resources

Cap-It™ Clip-Style Multipack Carton for PET Plastic Bottles

Cap-It™ is a recyclable paperboard clip solution for PET plastic bottles with neck rings. This multipack beverage packaging is an alternative to plastic rings and shrink film packaging.

Cap-It features an intelligent design that maintains pack integrity through the supply chain. On-shelf differentiation is achieved via a generous billboarding area, that still allows good visibility of the bottles.

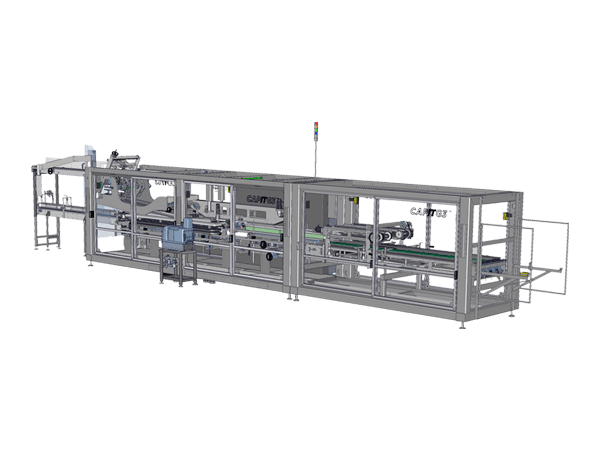

Cap-It can be packaged with any of our Cap-It machinery equipment, including the Cap-It 2 and our new generation machine, AutoClip™ CIG3, that runs at higher speeds and provides enhanced bottle stability.

Quick Links

See Cap-It in Action

This intelligent carton design provides on-shelf differentiation by offering the opportunity to print high-impact graphics on the paperboard while leaving the bottle visible to the consumer.

Asahi Soft Drinks Launches Cap-It™, a Fully Recyclable Clip-Style Carton for PET Bottle Multipacks

Asahi Soft Drinks needed a new multipack solution

for their Wilkinson Sparkling Water range in

response to increased production volumes and

the shift from cans to PET bottles for soft drinks

Related Machinery

Related Finishes and Enhancements

Graphic Packaging’s 2024 Impact Report: Toward a Better Future

July 10, 2025

ATLANTA, July 10, 2025 – Graphic Packaging Holding Company (NYSE: GPK) (“Graphic Packaging”), a global leader in sustainable consumer packaging, today announced the release of its 2024 Impact Report. The report highlights the company’s progress toward its Better by 2030 commitments announced last year, as part of a multi-year Better, Every Day sustainability initiative.

Grounded in its Vision 2030 business strategy, Graphic Packaging’s Better by 2030 sustainability goals outline actions the company is taking to:

- create better packaging designed to drive circularity.

- do better for people through safer work environments, engaging employees and local community involvement.

- shape a better future for the planet by reducing its environmental footprint and sustaining forests.

“Our Vision 2030 strategy places more focus than ever on innovation across our business,” said Graphic Packaging President and Chief Executive Officer Michael Doss. “Combined with our foundational commitment to sustainability, we are positioned to meet growing global demand for packaging innovations that are more circular, more functional and more convenient than existing alternatives.”

Highlights from Graphic Packaging’s 2024 Impact Report include:

Better Packaging

- Approximately 1 billion plastic packages replaced with paperboard packaging

- 97% packaging products sold characterized as recyclable1

- More than 130 new patent applications filed

Better for People

- Over 20,000 employee engagement survey participants (87%)

- 47% increase in Employee Resource Group participation

- 98% of global sites implemented Health Safety and Environment (HSE) Excellence System

Better Future

- 70% of EMEA electricity use to be covered by new virtual power purchase agreement (VPPA)

- 89% of purchased forest products sustainably sourced

- Approximately 1 million metric tons of our generated waste materials recycled

Toward 2050 Net-Zero Aspiration

Better by 2030 includes near-term climate action goals that Graphic Packaging is taking to advance its aspiration of net-zero greenhouse gas (GHG) emissions by 2050 (in accordance with the Paris Agreement and U.N. Sustainable Development Goal 13). These goals include validated science-based targets to reduce GHG emissions across the company’s operations and value chain, as well as commitments to increase the use of renewable fuel and electricity.

“We identified several ways to make sizeable GHG reductions, including upgrading to more efficient biomass boilers and steam turbines for cogeneration of steam and electricity at two of our wood-based paperboard manufacturing facilities,” said Graphic Packaging Vice President and Chief Sustainability Officer Michelle Fitzpatrick. “We are also exploring options to switch to 50% or more renewable electricity across all of our operations.”

Graphic Packaging’s first VPPA, announced in 2024, supports planned solar projects in Spain and is expected to come online in late 2025. This will enable packaging operations in Europe to match 70% of the region’s total electricity demand with renewable energy attribute certificates.

“Climate change remains one of society’s most pressing challenges, and we are firmly committed to doing our part to limit global warming by achieving net-zero emissions by 2050,” Fitzpatrick said.

Download the 2024 Impact Report

Graphic Packaging reports in accordance with the Global Reporting Initiative and Sustainable Accounting Standards Board Containers and Packaging standards along with providing information aligned with the Task Force for Climate-Related Financial Disclosures framework and the U.N. Global Compact Communication on Progress.

See the complete 2024 Impact Report: https://www.graphicpkg.com/sustainability/sustainability-reporting/

Learn more about what’s driving our sustainability strategy: https://www.graphicpkg.com/news-events/circular-packaging-2024-impact-report

1 Defined as widely recyclable, locally recyclable, or conditionally recyclable.

# # #

About Graphic Packaging Holding Company

Graphic Packaging designs and produces consumer packaging made primarily from renewable or recycled materials. An industry leader in innovation, the Company is committed to reducing the environmental footprint of consumer packaging. Graphic Packaging operates a global network of design and manufacturing facilities serving the world’s most widely recognized brands in food, beverage, foodservice, household, and other consumer products. Learn more at www.graphicpkg.com.

Contacts:

Media: Comms@graphicpkg.com

Investors: Investor.Relations@graphicpkg.com

Related News

Working Toward a Better, More Circular Future

July 10, 2025

Discover sustainable packaging innovations that drive positive environmental outcomes in Graphic Packaging’s 2024 Impact Report.

At Graphic Packaging International, every decision we make is driven by our purpose: to package life’s everyday moments for a renewable future.

Today, more than ever, sustaining our environment for a renewable future can feel insurmountable. But we’re optimistic. Guided by our Better, Every Day sustainability promise, we consider how our actions can help address not only global sustainability issues that touch consumer packaging (like resource scarcity and climate change), but also broader social aspirations to create lasting, positive impacts.

Part of this promise is to create better, more circular packaging, which can help us lessen the impact of consumer packaging (including packaging for food and household products) on our planet.

Our 2024 Impact Report underscores our foundational commitment to sustainability, showcases the innovative strides we made and highlights our aspirations for the years ahead. Click here to read the 2024 Impact Report from Graphic Packaging.

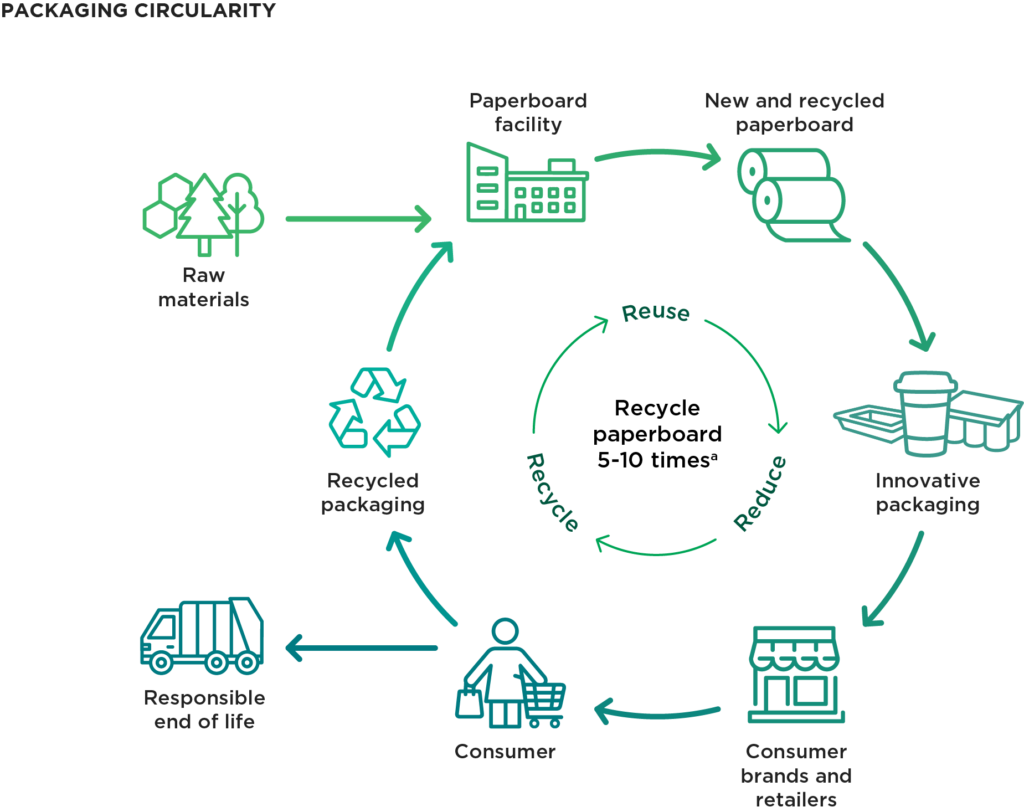

What Is Circularity?

It may not be trending on our social media feeds, but the circular economy reached “megatrend status” last year, according to the Circle Economy. People are discussing, debating and writing about the concept (in its simplest terms) of using more renewable raw materials and keeping materials in circulation longer.

That means reducing, reusing and recycling products at a consumer level. It includes repairing, refurbishing and remanufacturing products. It also means repurposing and recycling at a business level, and, perhaps most importantly, reducing by design at the start.

Not only is circularity a way to achieve sustainable consumption and production but also other interlinked sustainable development goals, like climate action. Combining circular approaches with renewable energy and energy efficiency efforts is the only way to achieve climate action targets, claims the U.N. Environment Programme.

Despite its growing popularity, circularity in practice has declined in recent years.1 Meanwhile, consumption of natural resources continues to grow.2

But there’s a way to close the gap, according to The Circularity Gap Report. Nearly one-fifth of the materials put on the global market are made from new, non-renewable resources that are hard to recycle. Alternatively, companies could minimize this waste from the outset by using renewable and recycled materials and designing more circular products. Getting this chunk of materials back into circulation would significantly bump global circularity.

“Our work to promote the circular economy has led to groundbreaking consumer paperboard packaging solutions that reduce dependency on single-use plastics and are designed to be recovered and recycled.”

Michelle Fitzpatrick, Vice President and Chief Sustainability Officer, Graphic Packaging

What Is Circular Packaging?

Circularity is about more than just recovering and recycling materials at the end of life. We are making our packaging and operations better and more circular every day by:

- Using more renewable, recycled and sustainably sourced raw materials.

- Designing packaging that can be easily recycled, reused or composted, as well as maximized for recovery and conversion into new products.

- Designing “right-sized” packaging — using the minimum necessary materials for functionality and convenience.

- Manufacturing packaging using safer chemicals, more renewable energy and generating less waste.

Through our Design for Environment (DfE) methodology, we optimize circularity and reduce the environmental impact throughout the packaging lifecycle. DfE is about designing out excess material use and waste from the start and minimizing the use of new and non-renewable raw materials in favor of renewable or recycled materials. It enables the recovery of valuable materials to be used again and again, maximizing the number of lifecycles while still providing the functionality to protect products and avoid waste.

As a global leader in sustainable consumer packaging, we focus on innovations that meet today’s needs and support a better tomorrow. We collaborate with customers to create more circular, more functional and more convenient packaging solutions that support their sustainability goals, while aligning with evolving regulations and consumer expectations.

2024 Sustainability Highlights for Better Packaging

- 1 billion plastic packages replaced with paperboard packaging

- 97% packaging products sold categorized as recyclable3

- 130+ new patents filed

- 29 packaging innovation awards globally

Sustainably Scaling for Responsible Growth

In our DfE methodology, the carbon footprint of our products is another key indicator of packaging circularity. To reduce our carbon emissions, we’re:

- using renewable materials, such as paperboard made from sustainably sourced wood and recovered fiber, to reduce our reliance on fossil fuels.

- optimizing our manufacturing processes to consume less energy.

- reducing waste generated from manufacturing and sent to landfills.

- sourcing local materials and optimizing logistics to reduce transportation emissions.

- collaborating with suppliers and partners to reduce emissions using sustainable practices.

Now more than ever, companies are looking for suppliers to provide packaging with a lower carbon footprint that contributes to their climate commitments. So, as we scale our operations to meet the demand for more circular packaging, we are working to reduce GHG emissions associated with our operations and products by using more renewable fuel and electricity.

We are committed to doing our part to limit global warming. As announced last year, we aspire to achieve net-zero emissions by 2050.

Our first virtual power purchase agreement (VPPA) will enable us to cover 70% of our European packaging operations’ electricity use with renewable energy attribute certificates. The VPPA supports planned solar energy projects in Spain, expected to come online in late 2025.

Our teams also reduce operational waste and associated greenhouse emissions by creatively recovering and reusing materials. Across our global operations, we diverted 69% of our generated waste away from disposal. We recovered more than 1 million metric tons of materials for recycling, including 99.8% of our generated paperboard waste.

And in our supply chain, we continue to source wood materials from local, sustainably managed forests where forest renewal and biodiversity can be safeguarded. We sustainably sourced 89% of the total forest products we purchased in 2024.

In addition to these projects and milestones, we continue to explore many other ways to sustainably scale our innovation capabilities, our operations and our supply chain. Check out the full 2024 Impact Report to see how we strive to do Better, Every Day.

“As we continue this next phase of our company’s growth, I’m confident our commitments to circularity and sustainability will enable us to continue creating value for customers, consumers, employees and shareholders alike.”

Mike Doss, President and Chief Executive Officer, Graphic Packaging

Better by 2030 — and Beyond

Our Better by 2030 sustainability goals — grounded in our Vision 2030 business strategy — outline the near-term actions we are taking to drive circularity for customers and consumers, for the planet and for our people.

But beyond 2030, we must overcome many more challenges to advance packaging circularity and further reduce GHG emissions to achieve net-zero emissions by 2050. We will need advanced recycling and composting infrastructure to capture and reuse 100% of produced consumer paperboard packaging; new, yet-to-be-developed, low emissions manufacturing processes; scalable carbon capture and storage technologies; and zero emissions transportation. Simultaneously, we will need to navigate highly dynamic regulatory landscapes, as the world adapts to global warming, biodiversity loss and increasing resource scarcity.

We need bold, passionate, engaged people to help us innovate new, more circular packaging solutions and sustainably grow our company. So, we’re investing in our people, who deeply care about our purpose and the planet.

We’re proud to say our workplaces are more engaged and safer than ever. In 2024:

- more than 20,000 employees (87%) participated in our employee engagement survey, and our engagement score increased by 4 percentile points.

- our Employee Resource Groups increased participation by 47%.

- 98% of our global sites implemented a Health Safety and Environment Excellence System to proactively prevent incidents, protect employees and the environment, and ensure regulatory compliance.

- we invested $2.2 million in our local communities. Employees packed meals for neighbors, taught students about recyclable packaging and renewable forests, and co-developed college courses on packaging technology and paper-related sciences.

Which brings us back to circularity. The circular economy is not only for the conservation of the environment but also the well-being of all, says the U.N. Environment Programme. It’s about better business, better value for consumers, better jobs and better equality. It involves us all.

We invite you to join us on our Better, Every Day journey. Take a look at our goals and the progress we have made in our first year, and ask us questions on LinkedIn. Stick around as we work toward a better, more circular future in 2030 and beyond.

1 Circularity (measured by the global consumption of secondary materials) dropped 21% from 2018 to 2023. Last year, it fell again from 7.2% to 6.9%, according to The Circularity Gap Report 2025.

2 According to the U.N. Environment Programme, “if we continue business as usual, we will double the extraction of materials in 2060 [compared to 2017 rates], far beyond the planetary boundaries.”

3 Defined as widely recyclable, locally recyclable, or conditionally recyclable.

Related News

Thank You

We’ve received your meeting request and are looking forward to seeing you at Pack Expo 2025!

Someone from our team will be in touch in one or two business days to confirm the details.

Be on the lookout for an email!

WHAT’S NEW

See What Else Is Happening at Graphic Packaging

Discover our latest news, insights, and innovations to supercharge your packaging decision-making.

Got a challenge? We’ve got ideas.

Sometimes the best ideas start with a simple conversation. Let’s talk it through at PACK EXPO 2025.

Tell us what’s on your mind, and we’ll take it from there.

Schedule a meeting with us at PACK EXPO, and let’s explore what’s possible.

Driving Packaging Forward: Discover Paperboard Innovation at PACK EXPO 2025

September 29 – October 1, 2025

Visit Us and Discover Our Latest Consumer Packaging Innovations

Consumer demand for packaging that relies less on plastic is rising fast, and for businesses looking for circular, functional, and convenient alternatives, our booth at PACK EXPO, West Hall W-914, is the place to start.

According to the latest Paper & Packaging Board research, 50% of U.S. consumers are concerned about plastic pollution. This concern, together with brand and retailer sustainability goals, and regulatory pressures relating to plastic and packaging, is driving innovation.

At PACK EXPO, you’ll discover our portfolio of paperboard packaging innovations that are designed to be more circular, more functional, and more convenient than the plastic packaging they replace.

Use voucher code 36X34 to unlock your free ticket to Pack Expo 2025 Las Vegas.

Explore our unique Boardio™ Immersion Room

Boardio™ paperboard canisters offer a sustainable, cost-effective alternative to rigid and flexible plastic, and metal containers.

The Boardio 3D immersive experience at our booth allows you to virtually explore the machine and understand the process of creating the canister.

See firsthand how Boardio can be tailored for sensitive food powders, snacks, coffee, confectionery, and more.

Plastic replacement innovation for beverage multipacks

Our clip portfolio for can and PET bottle multipacks offers minimal-material, recyclable paperboard alternatives to plastic rings and shrink film — delivering strength, sustainability, and great shelf presence.

EnviroClip™ Cans Clip-Style Multipack Carton

EnviroClip™ Cans is a clip-style multipack solution for canned beverages that uses Z-Flute™, a solid fiber design that adds strategic reinforcement where needed to deliver a strong clip that performs in both cold and humid conditions.

EnviroClip™ Beam Clip-Style Multipack Carton for PET Plastic Bottles

An alternative to plastic rings and shrink film, EnviroClip™ Beam is a paperboard clip-style multipack carton for PET bottles that uses minimal material and no glue.

EnviroClip™ Bottles Clip-Style Multipack Carton for PET Plastic Bottles

An alternative to plastic rings and shrink film, EnviroClip™ Bottles is a paperboard clip-style multipack carton for PET bottles.

KeelClip™ Clip-Style Multipack Carton for Cans

KeelClip™ is a paperboard clip-style multipack solution that replaces plastic rings and shrink film. It provides an enhanced user experience, great merchandising appeal and has an integrated high-speed machinery solution.

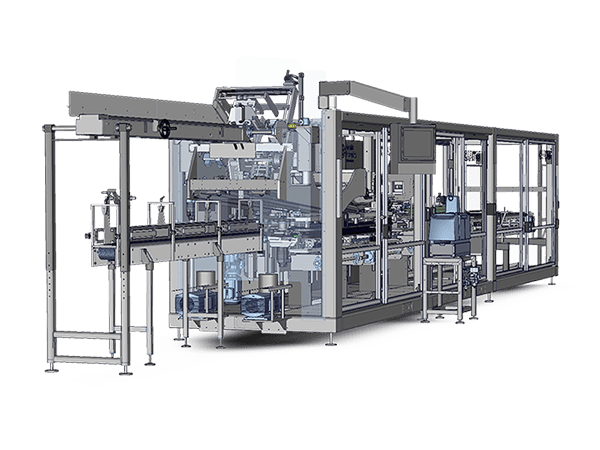

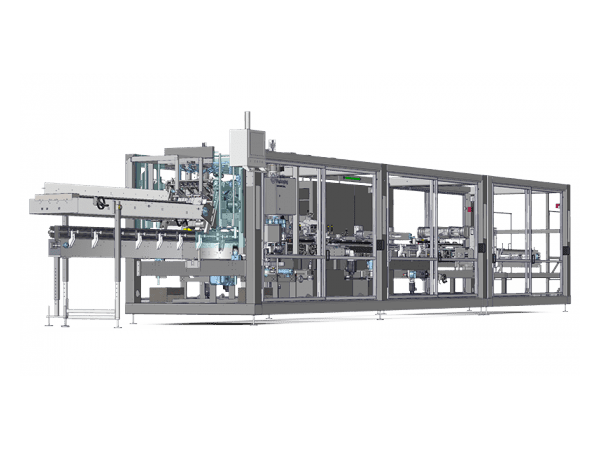

Integrated machinery solutions

In today’s competitive manufacturing landscape, efficiency and innovation are key to staying ahead. Our advanced machinery portfolio leverages flexible automation and next generation technology to navigate operational challenges and meet complex automation requirements.

At our booth, see AutoClip™ SplitClip™, a continuous-motion machine that applies the EnviroClip™ clip-style multipack carton to PET bottles and cans already in trays in a single clipping application.

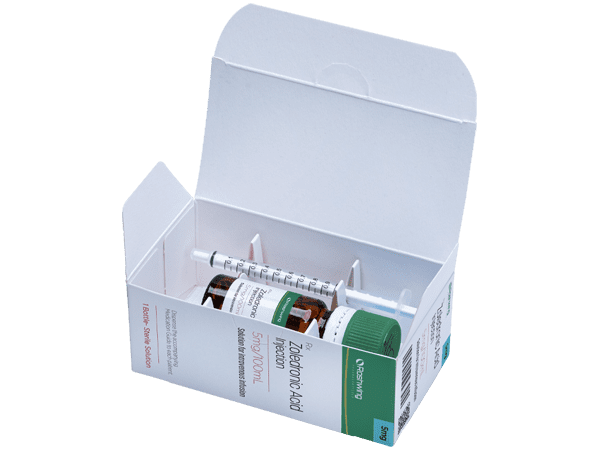

Discover healthcare packaging that safeguards safety and supply chain

As the healthcare market grows more complex and highly regulated, packaging must evolve. We offer packaging for prescription and over-the-counter medications, medical devices, eyecare and animal health, all built on GMP-compliant standards.

From tamper-evident cartons and child-resistant packs to anti-counterfeit features and track-and-trace capabilities, we help safeguard both patients and supply chains.

Tamper-Evident Packaging Measures

Tamper-evident packaging provides visible evidence to the end user that the product has not been tampered with. For pharmaceuticals, tamper-evident packaging is a requirement, while for other products it offers security throughout the supply chain and to the consumer.

Child-Resistant Packaging

Often used for pharmaceuticals, medical devices, and other non-food consumer products, child-resistant packaging can protect children and vulnerable consumers from harm while still being intuitive and easy for those not at risk to open.

Anti-Counterfeit and Grey Market Coding Packaging Measures

Consumers expect authenticity when buying a premium product, and for the pharmaceutical industry the guarantee of authenticity is vital to maintain patient safety, but high-value markets are attractive to counterfeiters. Our state-of-the-art packaging solution can help prevent counterfeiting to ensure your brand integrity is maintained and patients are protected.

Serialization and Track and Trace Packaging

Meet regulations while protecting patients from counterfeit medications with pharmaceutical serialization and track & trace technology for packaging.

Pet care packaging that performs

With the humanization of pets comes higher expectations for pet food and pet care packaging. We offer high performance packaging formats for a wide range of applications including canned and pouched wet food, dry food, treats, toys, cat litter and more.

Smarter packs for home and garden

For home and garden applications, durability, safety, and ease-of-use are critical.

CleanClose™ is a paperboard alternative to plastic tubs and pouches for laundry detergent, combining tamper- and child-resistance with the flexibility to handle a broad range of pod counts.

Strength packaging formats include IntegraFlute™, built for the demands of wholesale and club store channels – delivering high compression strength and structural integrity without compromising sustainability.

Foodservice innovation

Today’s consumer appreciates the ease of take-out and delivery services and the overall experience of enjoying their preferred cold beverages or frozen treats. Using a cup that underperforms shortly after preparation results in excess condensation, melted treats, and separated blends for guests.

Cold&Go™ insulated paper cold cups deliver the performance consumers expect – keeping drinks colder and in premium condition for longer compared to plastic cups. With a rigid feel and premium print capabilities, they’re an ideal alternative to plastic cold cups.

Our bakery packaging delivers supply chain efficiency, on-shelf differentiation, and standout branding – with a lot less plastic. From grease-resistant barrier performance to crisp die-cut windows, these packs strike a balance between functionality and visual impact.

Grab your free ticket to PACK EXPO

Use voucher code 36X34 to unlock your free ticket to Pack Expo 2025 Las Vegas.